Australian company Amcor is one of the world’s largest packaging manufacturers. With 4,000 staff worldwide, Amcor produces glass bottles, aluminium cans, cartonboard, corrugated boxes and flexible plastic.

Amcor is always looking for ways to improve its energy efficiency and reduce its environmental footprint. For example, the company conducts rolling energy audits and benchmarking across its operations.

As part of this process, Amcor identified energy saving opportunities at a number of plants, including addressing inefficiencies in the use of compressed air at its Revesby aluminium can manufacturing plant, located in south-west New South Wales. Compressed air is used heavily in the production of aluminium cans, including to press out cans from sheets of metal and to convey them around the plant.

As the Revesby site produces around 750,000 million cans each year, even small improvements in efficiency can have large flow-on benefits in terms of cost and the environment.

A $43,758 grant from the Australian Government’s Clean Technology Investment Program has enabled Amcor to improve the energy efficiency of the Revesby plant by enhancing the air compressor technology used on site.

Amcor’s Group Manager of Resources and Energy, Peter Dobney, says the grant has been instrumental in allowing the company to improve its plant in a challenging investment climate.

“As economic conditions have tightened, it’s become harder to get energy efficiency projects up and running. Companies need a reasonable payback from their investment,” says Mr Dobney, who is part of Amcor’s Sustainability Team. “The grant helped to get a project up and running that may not otherwise have been funded.”

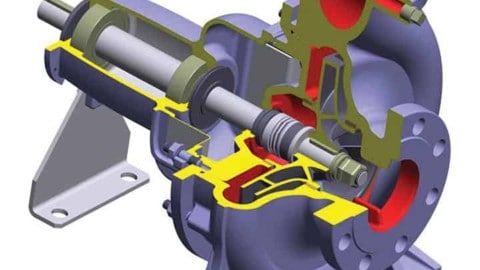

The grant is helping Amcor replace its inefficient high-pressure air compressor with a variable-speed drive unit. High-pressure compressed air is used for ejecting cans from moulding machines. The new system has the capability to adjust to peaks and troughs in demand, delivering a more efficient production process.

In addition, Amcor is using the funding to re-gear its current low-pressure air compressor, which produces more air than required. Low-pressure compressed air is used for the ‘necking’ process, which shapes the top and bottom of the cans. The new arrangements will produce the correct quantity of air, reducing energy requirements at the Revesby site.

Further, the company is installing cutting-edge air monitoring systems to ensure the most efficient processes are being used, and fitting variable-speed drives to new cooling tower pumps and fans.

By undertaking these steps Amcor expects to reduce its carbon emissions intensity by 5 per cent , and decrease its annual energy bill by $87,000. The Revesby grant is one of nine Clean Energy grants Amcor has received from the Australian Government.

Mr Dobney says Amcor staff members have reacted positively to the grant, and are increasingly approaching the company’s Sustainability Team with ideas for other energy efficiency projects.

“Rather than us travelling to sites and saying, ‘We’re here to help’, Amcor staff are coming to us,” he says. “They’re saying, ‘Our power bills have gone up significantly, and what can we do to cut them?’ Grants like those offered by AusIndustry help make such projects a reality.”

Washing away energy use

Amcor has also received a $186,408 grant from the Australian Government’s Clean Technology Investment Program, to install variable speed drives on 13 of the spray pumps at their Rocklea facility in Queensland so they don’t need to operate at full capacity all the time.

Each year, Amcor’s Rocklea facility in Queensland produces over 900 million aluminium cans for the beverage industry. After the production process, these cans need to be thoroughly cleaned before printing, and again before they are sent to Amcor’s customers. During the cleaning process, the cans are spray washed with detergent and rinsed to ensure they are free from lubricating oil and printing residue.

In recent years, Amcor scaled back its water use to conserve this precious resource and reduce costs. The packaging company uses a cascade system to recycle water during the cleaning process. This system uses fixed-speed pumps to pump water through each stage of the can washers.

“Variable speed drives will help us cut energy use, save water and reduce carbon emissions,” says Mr Dobney. “It’s the kind of technology we can easily apply to our other beverage can sites.”

The company is also using the funding to install oil sump heaters in 12 can body makers, introduce energy efficient lighting with built-in controls, and install high-efficiency vacuum pumps for conveying cans.

Amcor expects to reduce site-wide carbon emissions intensity by 10 per cent and save $200,000 in annual energy costs.

Amcor has received the following additional Clean Technology Investment Program grants:

• $80,997 to upgrade lighting, improve boiler efficiency and install a central control system at its Bohle facility in Queensland.

• $78,379 to improve insulation at the Preston plant in Victoria.

• $254,788 for a number of measures, including installing insulation, at the Rocklea facility in Queensland.

• $70,924 for a number of measures, including upgrading lighting, at the company’s corrugated box manufacturing facility in Brooklyn, Victoria.

• $44,240 to replace coolant pumps and upgrade motors in the company’s Western Australian premises.

• $45,000 to install voltage optimiser units in Victoria.

With initiatives funded by the grant, Amcor expects to:

• reduce carbon emissions intensity by 4.5% annually

• reduce energy costs by $80,000 each year.

Clean Technology Investment Program

The Clean Technology Investment Program provides incentives for manufacturing businesses to invest in energy efficiency and reduce carbon emissions. The program is part of the $1.2 billion Clean Technology Program, an initiative under the Australian Government’s Clean Energy Future plan.

The Clean Technology Investment Program will support manufacturing businesses over seven years to 2017–18. Applicants need to demonstrate how the proposed project will improve energy efficiency and/or reduce carbon emissions, their ability to undertake the project, and how it will maintain or improve the competitiveness of their manufacturing business. ■

For more information visit ausindustry.gov.au, telephone 13 28 48 or email [email protected].