By Ruth Elfassi-Kamer

Providing reliability, consistency and meeting drinking water quality at a water treatment plant can be an ongoing task for water authorities in Australia. The Australian municipal water market will also face an additional challenge in meeting the requirements of the Australian Drinking Water Guidelines 2011 (ADWG2011), which demand a higher level of water quality and closer monitoring than the preceding guidelines (ADWG 2004).

The following pilot study demonstrates the effectiveness of Amiad’s Automatic Micro-fibre (AMF) self-cleaning filter technology as a polisher filter reducing turbidity, total suspended solids and iron levels, while enabling consistent output results.

This case study was undertaken to ensure that the reliability of the filter and the water quality (including iron and turbidity levels) achieved, met both the local government potable water standards for treating bore water and the national requirements. The local government standards are actually stricter than ADWG2011 for iron and manganese levels, requiring 0.1 ppm of iron (rather than 0.3 ppm, in ADWG2011). At this low level of iron a low turbidity is also expected.

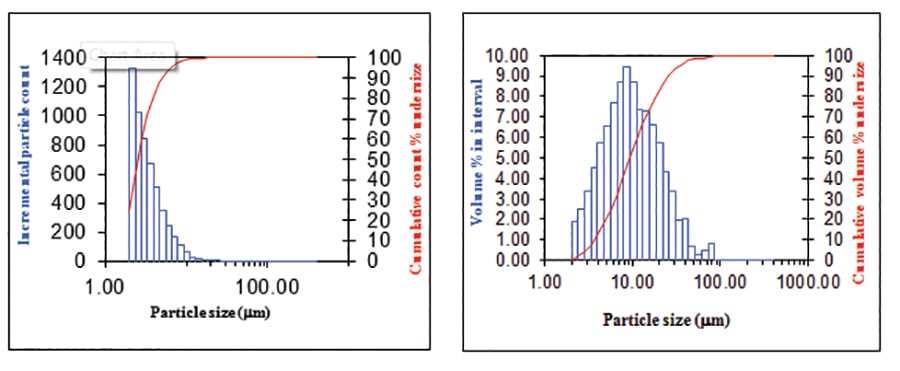

At the end of 2013, Amiad Water Systems received an enquiry from one of the Australia’s state government water authorities to assist with a filtration solution on one of their existing water treatment plants. The water treatment plant consists of an iron removal scheme incorporating oxidation, flocculation, continuous wash upflow sand filtering and disinfection. Following investigation, it was concluded that the filtered water in question contained residual iron particles in a ferric state (0.25- 0.35 ppm) and had a turbidity level around 0.6 NTU. Particle size distribution (PSD) analysis (Figure 1) demonstrated that total particles were greater than 2 µm, and based on volumetric tests the median particle size was around 10 µm. The local water authority’s standards for potable water when treating bore water are actually stricter than ADWG2011, requiring 0.1 ppm of iron (rather than 0.3 ppm). At this low level of iron a low turbidity is expected. Lower concentrations of iron in the treated water will mean less iron deposited in the reticulation system, lowering the chances of dirty water events.

As the iron particles were in the ferric state and at a minimum size of 2 µm, the Amiad micro fibre self-cleaning filter with a 2 µm cassette package was chosen to resolve the problem on site. Amiad and the local water authority collaborated to conduct a pilot test. A pilot plant is essentially a smaller scale simulation of a treatment process. It may be used to test a proposed process with particular raw water or to evaluate different operating conditions for an existing plant.

The main criteria for this pilot were:

- (i) To test the Amiad AMF filter for its operation reliability;

- (ii) To perform performance testing of water quality pre- and post AMF filter for iron and turbidity;

- (iii) To determine operational parameters for the large design scheme from the small-scale pilot trial.

1 X 2” AMF36K with 2 µm cassette (Figure 2) was installed on site where it was connected to a data logger that monitors and reports inlet and outlet turbidity, differential pressure, and inlet and drain flows. The pilot has now been running for few months and has been found capable of testing water at various flow rates up to 20 m³/h.

Figure 2: AMF filter, pilot skid consist of feed pump, instrument, AMF filter, and control and data logger.

Why was the Amiad AMF chosen?

Over the past 40 years, Amiad Water Systems (www.amiad.com) has developed a range of compact automatic and manual self-cleaning filters, incorporating innovative technology characterised by low operating costs and short capital payback. In addition to being used as a polisher filter for iron and turbidity polishing, Amiad’s automatic microfibre filters are typically installed in drinking water applications where they can protect against Cryptosporidium and play a vital role in effluent treatment processes, membrane pre-filtration protection, recirculation-water filtration systems, cooling tower main and side-stream filtration, stormwater filtration, and off-shore water injection projects.

The AMF filter was developed by aligning the concept of fibre filters with 21st century values, including minimising waste, reducing handler exposure to captured materials, chemical optimization, and lower operating costs. In short, AMF delivers clean water with clean technology.

The AMF filters both inorganic and organic particles as water flows through multi-layered microfibre cassettes. These are attached to collector pipes as a cartridge package. As with wound cartridge filters, the diameter of the fibre and how it is wound determines the degree of filtration the cassette can deliver, ranging from 20 to 10, 7, 3 or 2 µm. Particles are trapped between the fibres. When a target pressure or time differential is reached across the filter, the self-cleaning cycle is activated using a high pressure stream of water (jet mechanism).

The AMF filters are designed with a large filtration area and are available in three different sizes: AMF36K, AMF93K and the AMF370K which is capable of running up to 300 m3/h per unit subject to flow, filtration degree and beginning water quality.

Amiad’s fibre technology has been evaluated by the UK Drinking Water Inspectorate (DWI) and approved by the UK secretary of state for use in the UK public water supply. The AMF filter with 20 µm cassette achieved the California Water Recycling Criteria (known as Title 22), where filtration technology must achieve the required turbidity level. The Title 22 approval identifies the Amiad AMF as a complement to an approved disinfection process such as chlorine, UV or ozone. Furthermore, it has been accepted as a pre-disinfection filter in several areas of Japan, Israel, and recently been re-tested in New-Zealand in a laboratory environment with a live Cryptosporidium which demonstrated a 3-4 log reduction value.

Fine particle filtration to allow good polishing of water and deliver consistent output results while also meeting ADWG2011 can be a difficult task. The AMF filter is a viable option to overcome this challenge. Because the filtration medium is constructed of fine fibre threads wound in layers, the Amiad technology combines the advantages of surface and depth filtration in a compact design. Figure 3 shows the particle filtration quality of the microfibre cassette (MFC) at different filtration grades. Spherical particles have been added to inlet water so that the reduction of these particles between inlet and outlet of the AMF filter can be measured. The AMF’s cassette at all filtration grades provides a very high percentage removal of particles. These results demonstrate the depth filtration ability that the AMF filter provides. Even though filtration levels can be selected as low as 2 µm, the main advantage of the system is the large filtration area with a small footprint. The high filtration area results in reduced backwash frequency with the further advantage of low wastewater production. For instance, in the AMF36K (up to 20 m3/h) backwash is only 0.5 m3 water per cycle.

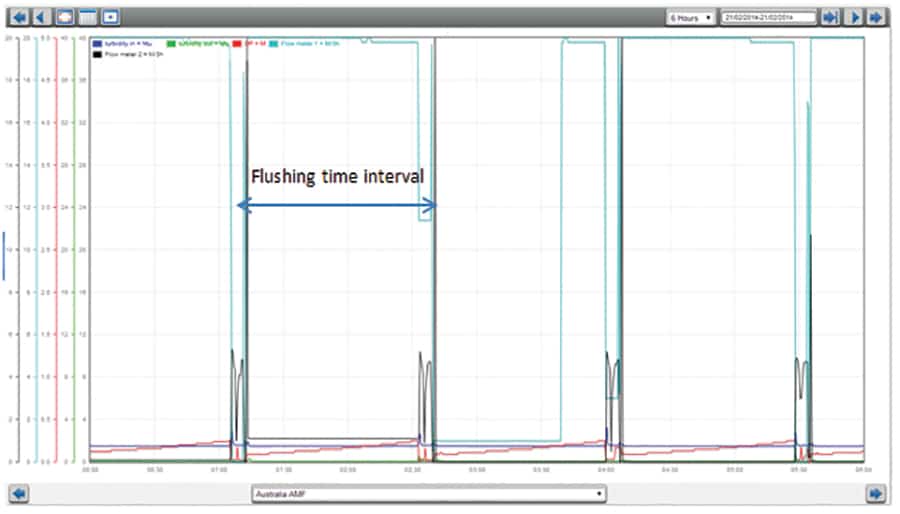

Using the ability to access online monitoring (Figure 4) and accordingly optimize the operation conditions of the pilot plant, a set of flow rates were tested. These were 7, 10, 12, 15, 17, 18 and 20 m³/h. At each of the different flow rates the water quality improvement and the functionality of the plant were studied.

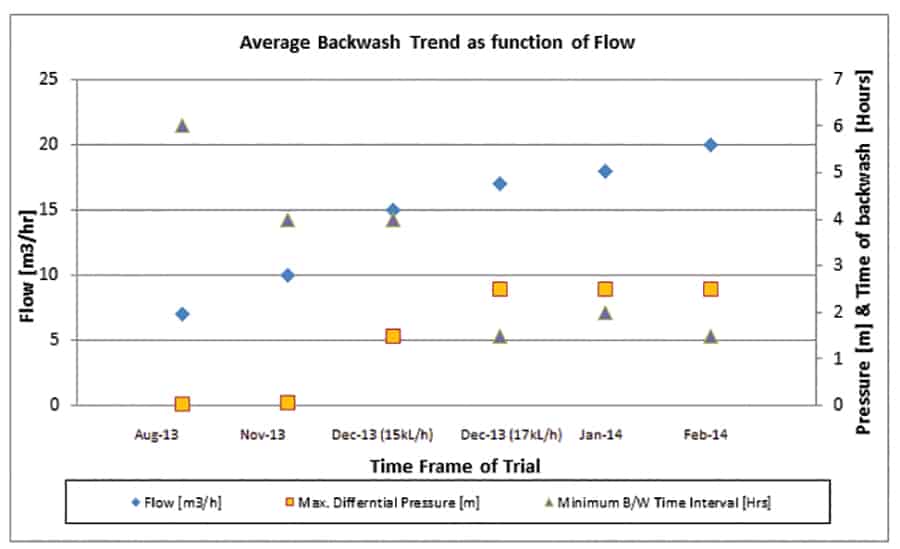

Summaries of the average results (dP, flow, turbidity) collected for each flow rate are depicted in Figures 5 and 6. These results were derived from 24/7 online monitoring, which recorded the reading every few minutes.

Figure 5 shows the average backwash interval time as a function of flow rate. The higher the flux (filtration rate, m³/h/m²) the quicker the differential pressure develops on the cassette, resulting in shorter interval time between flushes. At lower flows (<15 m³/h, which is typically the recommended flow for such application) the AMF flushed only when a set time interval had elapsed resulting in one flush every four to six hours. As the flow increased the flushing frequency increased to once every two hours. It is important to note that the AMF36K at 20 µm filtration degree would be typically designed to operate at maximum of 30 m³/h (subject to feed water quality). At finer filtration degrees and in order to allow maximum efficiency of the operation one may consider operating at lower flow rates. In this study the AMF36K at fine filtration degree of 2 µm operated at high flow of 20 m³/h, yet provided a reliable and effective operation even in such demanding conditions.

Online Turbidity and sampled iron results are verified by a third party laboratory.

Figure 6 describes the water quality before and after the AMF filter as a function of flow. At the pilot plant, the Amiad AMF filter consistently provided iron level of less than 0.02 ppm and turbidity less than 0.2 NTU, regardless of the differing flow rates.

The AMF filter controller comes with human interface monitoring providing a user-friendly operation, requiring minimum onsite operation and maintenance. At the pilot, the AMF was flushed using some of the filtered water and was inspected during the pilot testing. During this period it demonstrated no appreciable wear and tear. The cassette was in excellent condition without chemical cleaning having taken place.

Overall, the AMF filters performances met the local water authority’s high standard of water quality, as well as the ADWG2011 guidelines. Throughout the entire period of pilot testing, the AMF filter has been reliable and effective in its operation and filtration performance. The Amiad microfibre self-cleaning filter provides a highly effective filtration solution down to 2 µm, reducing iron and turbidity levels. The pilot testing continues to operate in order to conclude the commercial design scheme.

Acknowledgments

The author wishes to acknowledge the local water authority for participation and support of this trial. The author also acknowledges Peter Spencer, David Masters, Michael Jovanoski, Rani Pisk, Syed Tanveer-Alim, Dale Harris, Jamie Pickford, and all other personnel involved in planning, designing, commissioning and operating the pilot.