The pump industry relies on expertise from a large and varied range of specialists, from experts in particular pump types to those with an intimate understanding of pump reliability; and from researchers who delve into the particulars of pump curves to experts in pump efficiency. To draw upon the wealth of expert knowledge the Australian pump industry has to offer, Pump Industry has established a panel of experts to answer all your pumping questions.

This edition of Ask an Expert will look at technological advances for progressive cavity pumps with quick and easy maintenance solutions.

Q: What steps are progressive cavity pump manufacturers taking to make their product easier to maintain?

A: Occasionally, after a progressive cavity (PC) pump has been in use for a while, maintenance work will need to be carried out. Various PC pump manufacturers are expanding their portfolios with easy-to-use maintenance concepts to save customers time and money when working on the pumps.

Standard PC pumps

The rotating parts of a pump can eventually wear down and need to either be exchanged or readjusted. New technology from manufactures offers quicker and easier access to the rotor and stator unit and even ways to readjust them for increased flow. Along with the rotor end of the pump, there are solutions for working on the drive side pump components to remove the entire rotating unit without having to disassemble pipework, suction housing and/or other components.

PC pumps with a feed hopper

Pumps with feed hoppers present a special type of challenge. Not only do they convey viscous products with little flowability, but also maintenance on these pumps is time consuming and complicated due to valves and hoppers obstructing access to the pump.

To combat this issue, PC manufacturers have designed various ways to access drive side along with rotor side joints and parts. One solution is to make part of the casing movable so that seals and even the drive are quickly installed or removed on-site. With access to both the front and back areas of the pump, customers have two technologies at their disposal for exposing components for maintenance without having to disassemble pipework, valves or the feed hopper. This unimpeded access to the relevant pump parts simplifies all subsequent work on both pump ends.

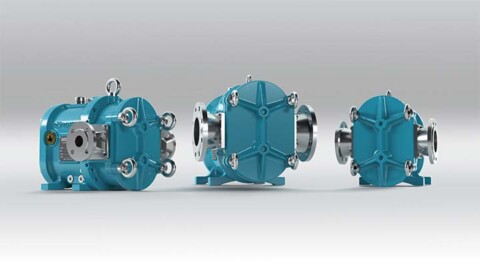

A modern PC pump design with “maintain in place” principles.

Q: What benefits can customers experience/see with easy to maintain PC pumps?

A: Intelligent maintenance concepts reduce downtime and save time and costs.

- Significantly reduced maintenance costs:

Easy access to rotating parts and joints without disassembling extra components, casing parts and/or pipework - Preventive maintenance:

Regular, easy and quick check-up of components - Increased uptime:

Proactive inspection and maintenance ensures

trouble-free operation

These are just some of the ways PC manufacturers are looking to save you time and money.

An example of easy drive side and rotor side maintenance in feed hopper pump.

About the author

Peter Vila, Managing Director of SEEPEX Australia, is a progressive cavity pump expert. He has been involved with pumps for over 40 years. Peter spent the first five years repairing pumps and the following 35 years in technical sales, 20 of which have been with SEEPEX progressive cavity pumps.

Peter Vila, Managing Director of SEEPEX Australia, is a progressive cavity pump expert. He has been involved with pumps for over 40 years. Peter spent the first five years repairing pumps and the following 35 years in technical sales, 20 of which have been with SEEPEX progressive cavity pumps.

For more information on progressive cavity pumps, please contact SEEPEX Australia on (02) 4355 4500 or at [email protected].