The pump industry relies on expertise from a large and varied range of specialists, from experts in particular pump types to those with an intimate understanding of pump reliability; and from researchers who delve into the particulars of pump curves to experts in pump efficiency. To draw upon the wealth of expert knowledge the Australian pump industry has to offer, Pump Industry has established a panel of experts to answer all your pumping questions.

The pump industry relies on expertise from a large and varied range of specialists, from experts in particular pump types to those with an intimate understanding of pump reliability; and from researchers who delve into the particulars of pump curves to experts in pump efficiency. To draw upon the wealth of expert knowledge the Australian pump industry has to offer, Pump Industry has established a panel of experts to answer all your pumping questions.

Peter Vila, Managing Director of Seepex Australia.

Only five? Of course I’m biased, but here goes . . .

1. Wide application range

Progressive cavity pumps are particularly suitable for handling abrasive and even aggressive substances with all degrees of viscosity. They can be used on fluids at temperatures of between -20 °C and +180 °C and can transport products at capacities of 0.1L/h, up to 500 m3/h, independent of the discharge pressure or the DS content of the product. Differential pressures of up to 48 bar (and higher in special cases) are available.

2. Gentle, precise and trouble-free

Handling sensitive products often requires a pump with specific characteristics incorporating low shear rates, accurate metering/flow and minimum pulsation. Progressive cavity pumps incorporate all these qualities. Additionally, they have no check valves to clog the cavities within the pump, allowing the progress of pumped media from the suction to the discharge without restriction.

3. High suction lift capabilities

Progressive cavity pumps typically have excellent self-priming characteristics, even on gaseous liquids, with reliable operation at up to nine metres lift.

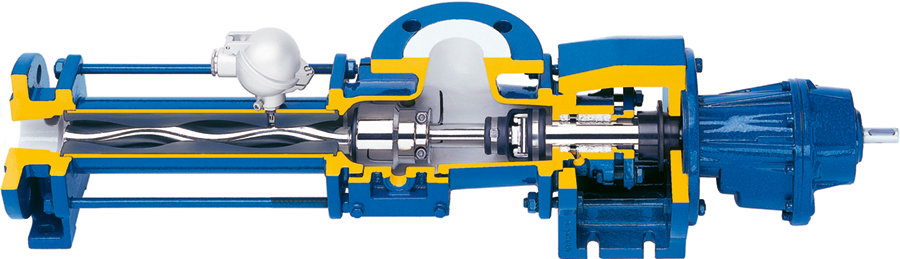

Cutaway of progressive cavity pump showing rotor, stator with dry-run protection, coupling rod with universal joints (one side with joint protector) and plug in shaft with seal area.

4. Versatile

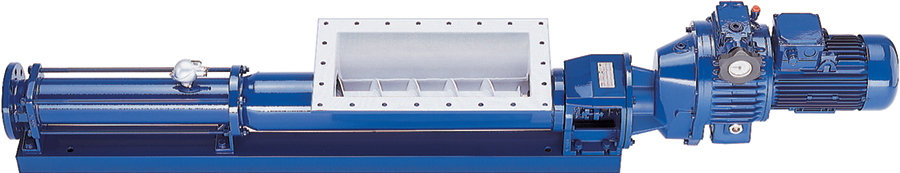

Integration of a progressive cavity pump into any facility is easily accomplished, as they can be installed horizontally, vertically or in almost any position. Pump flow is reversible with shaft rotation. Their versatility can be further enhanced by fitting various options, including open hoppers and numerous feeding arrangements, to assist non-flowable products into the pumping elements, the rotor/stator.

5. Service-friendly

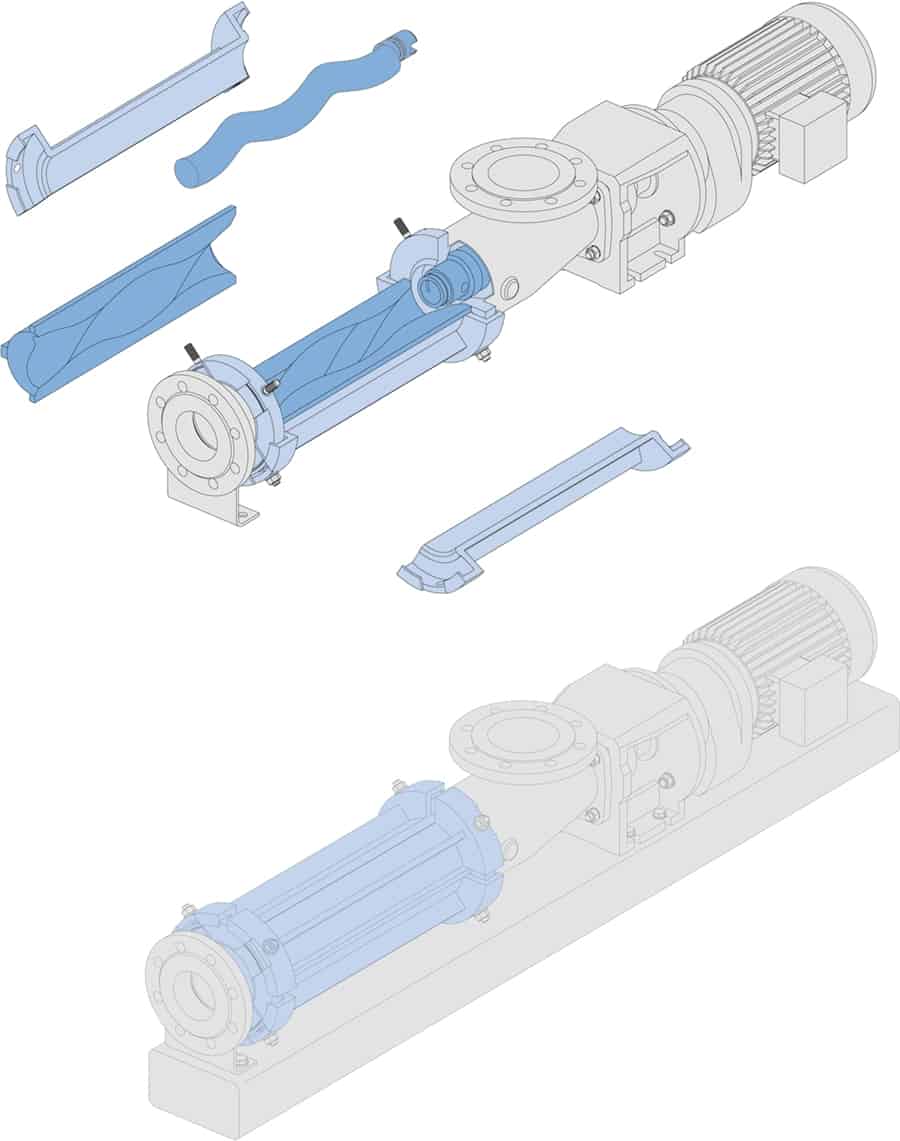

Well-designed progressive cavity pumps are known to be very service-friendly. Typical features include: a drive shaft plug-in connection, robust universal joints, reliable shaft sealing arrangements and more recently, the incorporation of special rotor/stator designs which greatly increase service life, while at the same time allowing in-situ rebuilds, thereby significantly reducing maintenance downtime.

6. Oh, that’s right, you only asked for five reasons, but hey, I’ve already said I’m biased and yes, I could happily keep going . . .

For more information on Progressive Cavity pumps, please contact seepex Australia on (02) 4355 4500

or [email protected].

Latest design in progressive cavity pumps allows in-situ rebuilds and also offers longer service life due to reclamping capability.