From the smallest pipes to the most powerful motors, protecting your fixed pipework against the effects of vibration, even in the most demanding operating environments, is a critical factor in any project’s design phase.

If overlooked, excessive vibration can cause serious damage to equipment, leading to a potential safety hazard for those in the near vicinity as well as having adverse environmental effects.

Type FSH Flame Protection covers

It is important for an engineer to identify how vibration is controlled in order to mitigate risk, damage or wear to a system. It is a common mistake to assume that adding pipe mounts or fixing the pipework to other ‘solid’ objects to prevent the pipe from moving will solve the issue. This may help in some cases but more often than not, the vibration and the problem is shifted to another position in the system.

Flexible expansion joints are the most effective tools that can be used to combat the potential devastation caused by uncontrolled or unrestricted vibration. Expansion joints that will make you feel those good vibrations.

Maximising throughput

Whether for tank trucks or power stations, flexible bellows have a lasting impact on a system’s performance and can restrict a system’s output. Choosing the right expansion joint that will go the distance will reduce the need for continual maintenance.

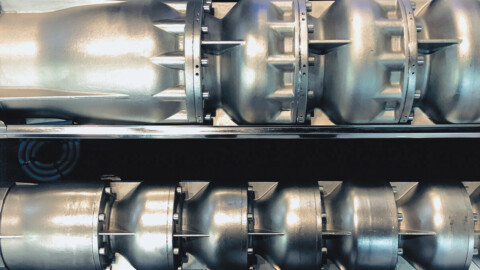

When you get to the bulk end of the scale, having access to an expansion joint for almost every industry and every application is important. With sizes from DN25 to DN4200, our expansion joints can handle the most demanding operating environments, from freezing arctic climates to power station engine rooms. The ERV-GS HNBR has the ability to constantly work up to +100°C and is fire resistant up to 30 minutes at +800°C.

ELAFLEX expansion joints cover a wide variety of fluids with global experience in industries such as wastewater, power generation, petrochemical, aviation, LPG, marine, food, dairy pharmaceutical and many more.

ELAFLEX expansion joints cover a wide variety of fluids with global experience in industries such as wastewater, power generation, petrochemical, aviation, LPG, marine, food, dairy pharmaceutical and many more.

Rubber has a limited resistance to heat and flame, Flame Protection covers, made of glass fiber fabric, with a cover silicone-Aluminium-glass fabric (certified acc. MED A1/3.13), reliably shields the expansion joint against heat and direct flames up to +800 °C for 30 minutes.

This partner content is brought to you by ELAFLEX. For more information, visit www.elaflex.com.au.