Towering eight storeys above Green Square’s town centre in Waterloo, 4km from Sydney’s CBD, is Australia’s – and the Southern Hemisphere’s – tallest man-made waterfall. Designed as a feature of the $400 million multi-residential development named after it, Waterfall by Crown Group, it is set into the wall of the building and surrounded by thousands of tropical plants. Pump Industry spoke to Waterforms International, the company behind the design of the waterfall, to find out more about the design of the feature, weir type and flow rate testing and the equipment driving it.

SJB was awarded the development project as part of the City of Sydney Competitive Design Policy with a proposal that was sensitive to urban grain, texture, built form and public realm – guided by an approach to open up the buildings and let the landscape in.

Inspired by cascading water and dense forests, the scale of Waterfall’s communal open space allows for the insertion of a significant landscape area, able to support large mature trees over time.

Lush gardens frame a tranquil outdoor ‘billabong’ and bamboo-covered walkway on ground level. The 22m-high waterfall is the first of its kind for a residential project in Australia and is only visible from within the development, adding a beautiful sense of tranquility to the grounds.

It is comprised of four water displays that are programmed to function alternatively as waterfalls or waterwalls, and in three main formats:

- All operating as waterfalls

- Two waterwalls and two waterfalls– the highest of the displays to be waterwalls

- All operating as waterwalls

At nightfall there is a lighting program that operates automatically, thrusting illumination from the ground level to the waterfall’s highest point, bringing a highly dramatic visual element to the display. Waterforms International’s Dirk Slotboom, the designer for the waterfall said, “The concept behind Crown’s Waterfall development was to create an urban oasis within the Waterloo area.

The brief to Waterforms International by the Crown Group was to create the highest man-made waterfall on a residential building in the southern hemisphere. “The project contained various levels of complexity that required new and innovative design principles to resolve.

Building the highest man-made waterfall in the Southern Hemisphere had its challenges from the outset, but what contributed to the complexity of the project was the narrow space between the buildings.” Other complex design challenges posed by the project included having water flow from eight storeys high in a high wind zone, with minimal noise and splash for residents.

“We constructed a full-size prototype and a separate plant room, designed to recycle water and to ensure the plants in the green wall are kept alive. What’s more, we designed the waterfall during Australia’s worst recorded drought, in a way that allows the waterfall to stop and start according to wind and weather conditions,” Mr Slotboom said.

The prototype weir from above.

Testing the design

As the project had no precedent and was a world first, it was necessary to build a full-size prototype on-site in order to test and perfect the weir design before construction began.

Multiple types of waterfall weirs (piano keys, radius, wave, and saw tooth) were tested on the prototype to see which one was not only visually appealing, but also able to pass all of the construction tests and achieve a successful outcome.

The testing involved the alteration of the type of weirs and the volume of water coming over the edge. This allowed the design team to refine the design and the optimum flow rate of the water, focusing on how the weir shapes affected the water trajectory.

“The final weir was selected due to the efficiency of the design to combat and compensate for the high wind zone caused by the narrow gap between the buildings,” Mr Slotboom said.

The team ultimately chose the piano keys weir type which is a fairly unique design where little fingers – similar to piano keys – help to control the water and make sure it falls vertically, while also ensuring it doesn’t fall or drift away from the building onto the walkway space.

Mr Slotboom said to create the effect of the waterfall there are two flows going over the surface. “The effect that we created, we had to have the wall wet and then we have the water rolling over the wet surface.”

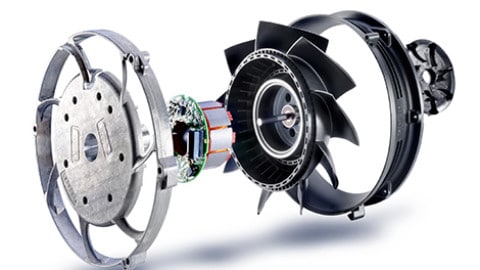

There are six weirs and spouts that create this effect, with pumps controlling the water flow.

Four water displays – dramatic lighting.

Overcoming project challenges

Two of the major challenges for the project were the narrow space between the buildings, and the noise and splashout zone affecting residents. Testing on the prototype was key to overcoming these. Mr Slotboom said the narrow space between the buildings creates a high wind zone and extends the resulting splash out zone.

“The solution was to split the display into two functions – waterwall and waterfall – to combat the high wind and splash out zones. The program allows the project to respond dynamically to weather and wind conditions while remaining functioning, rather than going

into immediate automatic shutdown.”

Tests were also conducted on the blade walls surrounding the waterfall that contain the drift of the spray. “The weir design was perfected at full-size prototype in order to address this issue before casting the weir in bronze. This weir was specifically designed and manufactured for this project and has not been used anywhere else in the world.”

To lessen the effects of noise and splash out zone on residents, multiple wind sensors were incorporated into the project in order to accurately adjust the water flow and contain the splash out zone, particularly during high wind periods.

This is possible with the use of variable speed pumps which adjust the flow rates of the water depending on such external conditions. When selecting the variable speed pumps, Mr Slotboom said environmental impact and energy efficiency are always high priority considerations when selecting equipment for any of Waterforms’ projects, regardless of size or complexity.

“A further consideration for the residents was to develop a unique solution to reduce any sound or splash issues. Special sound and splash screens were designed and developed and placed at specific angles to effectively deflect the noise and the splash out,” Mr Slotboom said.

“The design was further enhanced by incorporating flexibility into the angle of the screens so they could be adjusted depending on the season and the weather.”

A sustainable design

While the waterfall was not designed to be a mechanism to increase sustainability, it was designed with sustainability in mind. The water used for the waterfall is rainwater that has been captured and is continually recycled on a loop system, with pumps moving the water to the top of the waterfall before it falls again.

The rainwater and resulting recycled water are run through pump-driven sanitation and filtration systems to help maintain water quality, and prevent algae from growing on the walls.

Maintaining the system

Mr Slotboom said Waterforms International came into the project after most of the building was constructed, and the plant room space that had been designated was not sufficient for the equipment or to allow technicians to move around the equipment they needed to operate during service and maintenance while also keeping the plant area clean and tidy.

This created a challenge that required an innovative approach to overcome. “Waterforms designed a split level plant room that maximised the area that had been allocated by creating a mezzanine level which created a larger floor area within the same footprint,” Mr Slotboom said.

“Essentially the service and maintenance routine is designed to keep the water display functioning at its highest performance at all times and to fast-track any issues that may arise before they become problems.” Maintenance is particularly important as the living green wall requires highly sensitive consideration for the water treatment and sanitation systems.

“Due to the green living wall in close proximity to the waterfall it is imperative that the chemical balance is maintained in order to keep the plants free from any chemical damage while maintaining healthy treated water in the atmosphere and the ponds for the public and residents,” Mr Slotboom said.

“Regular service and maintenance will ensure this as all our service technicians are highly trained and experienced.” The team is also in close and regular contact with the Department of Health to ensure the system is chemically balanced correctly, produces water quality that is safe and healthy for the residents and general public, and doesn’t harm the plants.

Four water displays with minimal lighting.