Ebara has rethought the hydraulic design used in multistage pumps. Utilising the latest in computational fluid dynamics and design, followed by rigorous testing, Ebara has developed a unique impeller design that offers solutions and value to the customer – the Shurricane.

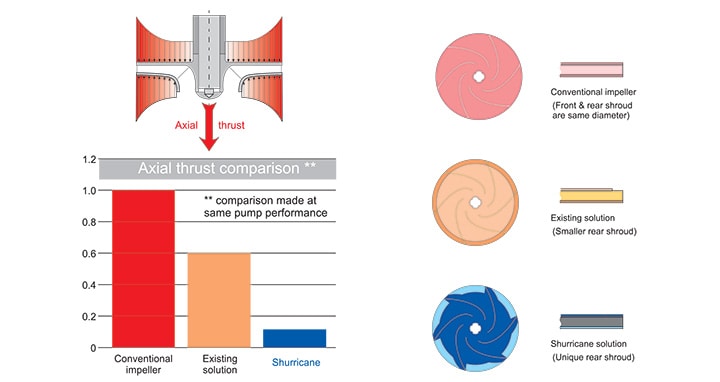

The imbalance of forces acting on the front and rear shrouds of a conventional impeller results in axial thrust. This thrust load is compounding in multistage pumps, and has to be allowed for in the pump design.

For pumps with conventional impellers, the existing solutions include having a thrust bearing built in the pump, or to use a special motor fitted with a larger thrust bearing. Both are costly and can be complicated. Another solution has been to simply have a smaller diameter back shroud to reduce the thrust.

Ebara has rethought the hydraulic design used in multistage pumps. Utilising the latest in computational fluid dynamics and design, followed by rigorous testing, Ebara has developed a unique impeller design that offers solutions and value to the customer.

The optimised shape of the Shurricane maintains high efficiencies and very significantly reduces the axial thrust – meaning that any standard IEC motor can be used and bearing life is improved.

Built like a Katana

A Katana is a traditional Japanese product manufactured with care and precision. Only years of experience can give the necessary capacity to build a masterpiece.

This is what Ebara does with its pumps. The result of over 100 years of Japanese experience in pump design and manufacturing, their pumps offer high quality performance, reliability, and cutting-edge technology.

Ebara’s vertical multistage pumps are manufactured in Italy to the highest standards of quality, and achieve reliable operating performance by means of strict technical evaluation criteria and control programs that involve the whole manufacturing process.

Suitable for a range of applications

The range of Ebara vertical multistage pumps are suitable for a wide range of applications, in the industrial, commercial and agricultural fields.

They can be used at water treatment plants (for reverse osmosis and filtration), for the pumping of hot or cold water for HVAC systems, for the pumping or boosting of water in general, and in boiler feed, irrigation and fire fighting systems.

The pumps can be coupled with any motor, anywhere. Optional materials are part of the unique hydraulic design, and there are optional connections for customers to consider.

Product features

Innovative hydraulic solutions

- Commercial motors can be fitted to all of the pump models without any modifications thanks to low pump axial thrust load

- Long life of the motor bearing

- Patent Application

Energy saving

- High pump efficiency with MEI (minimum efficiency index) > 0.7

- Fitted with high efficiency motors

- Suitable for use with Variable Frequency Drives for further energy savings

Piping connection options

- Various types of connections are available to best suit different installation requirements

- The external dimensions are to the industry standard, and are interchangeable with most other brands.

Easy maintenance

- The cartridge type shaft seal is able to be replaced without disassembling the motor bracket

- The spacer coupling allows easy maintenance without having to remove heavy motors 5.5 kW & above.

Smart plug solutions

- Air ventilation plug

- Water filling & sensor plug

- Commercial sensor fitting

- Tappings for suction and discharge pressure, and/or drain

This partner content is brought to you by Ebara. For more information, visit www.ebara.com.au.