Hoses are required in a variety of different pumping systems with a range of applications within various industries. They are frequently used in fluid transfer applications where rigid piping is undesirable, such as where the system may be moved between different water sources or discharge points and therefore needs to be easily portable. Hoses come in a range of types, including suction, discharge, layflat, NSF grade and high temperature discharge.

Using the right hose for the application is important for the success, operation and reliability of the pump, resulting in improved production rates and reduced maintenance costs. An incorrectly selected hose can result in premature failure, potentially bringing the entire operation to a halt. In order to select the right hose, there are several variables that need to be considered.

Selecting a hose

One method that can be used to find the right hose for the application is the STAMPED method – S(ize) T(emperature) A(pplication) M(edia) P(ressure) E(nds) D(elivery).

Size: When looking at the size of a hose, inside diameter, outside diameter and total length including fittings and tolerances need to be considered.

The inside diameter is important to obtain the proper flow rate. If the flow is too slow, the system performance will also be slow, but a flow rate that is too high will cause excessive pressure drops, system damage and leaks.

The length of the hose needs to take into consideration bending and flexing from movement and articulation, and to ensure there is no excessive stress caused at the crimped fittings. At maximum pressure, a hose connected in a straight line from one component to another can shrink by up to four per cent, so while extra length needs to be allowed for this, a hose that is too long will restrict flow which increases system pressure and reduces system efficiency.

The outside diameter comes down to weight and space. Where these are a concern, hoses with a smaller outer diameter can be used, offering a tighter bend radius. Otherwise if space is not a concern, some materials allow for a lighter weight hose without a reduced outside diameter.

Temperature: Ambient temperature and media temperature both need to be identified to select the right hose. If the ambient temperature – the temperature outside the hose where it is being used – is too low or too high it can adversely affect the hose cover and reinforcement materials, reducing its service life. The media temperature – the temperature of the media being moved – can have an even greater impact on the hose’s service life. If the temperature is too high for long periods of time, the rubber will lose flexibility.

Application: When looking at the application, the configuration, routing and orientation of the hose should be considered. “How will the assembly be used?” is the key question to ask, including type of equipment involved, environmental factors, mechanical loads, routing, type of hose fittings being used, and abrasion risk. Some applications will require specific hose features such as abrasion-resistance, and flexibility. Furthermore, the hose should comply with industry standards.

Media: The selected hose needs to be compatible with the media being conveyed, taking into consideration the presence of solids, pH level, flow rate and velocity. All parts of the hose need to be compatible including the inner tube, cover, fittings and O-rings. If the hose is not compatible with the media, it will have a decreased service life and its leak-free functionality can be compromised.

Pressure: The selected hose needs to have a maximum working pressure rating that is at or above the normal maximum hydraulic system pressure, taking into account momentary pressure surges. Fittings also need to be rated at or above the working pressure because if they are rated lower, the entire hose assembly will be derated.

Burst pressure also needs to be considered for some hose types. For hydraulic hoses, burst pressure is built-in as a safety factor and is often rated four times higher than the working pressure rating.

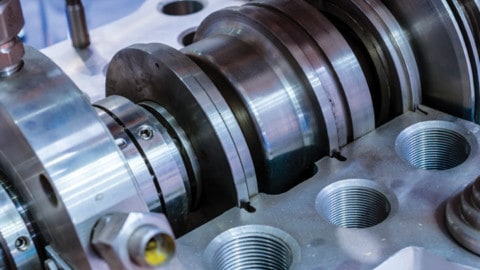

Ends: When selecting the ends for the hose, the hose style, type, size, orientation, attachment method, and whether it is coupled or uncoupled needs to be considered, as well as factors already discussed including application, pressure and media. The fitting connection is the weakest link of the hose and most of the cause of hose failure, so selecting the right ones is imperative to keeping the system operating at its best.

Delivery: Considerations for delivery include when is the hose required by, time needed to manufacture the hose and/or properly install and assemble the fittings, and whether the hose needs to be tested and certified. Once installed, a full inspection and/or re-testing should take place on a regular basis depending on the manufacturer’s recommendations. Worn out fittings, clamps, damaged hoses and missing safety devices should also be replaced immediately once identified.