The pump industry relies on expertise from a large and varied range of specialists, from experts in particular pump types to those with an intimate understanding of pump reliability; and from researchers who delve into the particulars of pump curves to experts in pump efficiency. To draw upon the wealth of expert knowledge the Australian pump industry has to offer, Pump Industry has established a panel of experts to answer all your pumping questions.

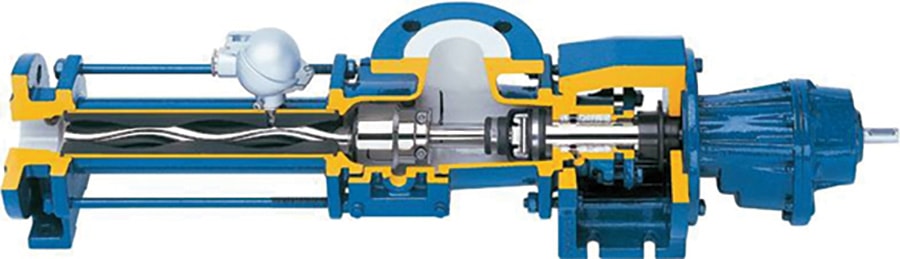

Progressive cavity pumps

Our progressive cavity pump expert is Peter Vila, Managing Director of SEEPEX Australia. Peter has been involved with pumps for 35 years.

Our progressive cavity pump expert is Peter Vila, Managing Director of SEEPEX Australia. Peter has been involved with pumps for 35 years.

He spent the first five years repairing them and the subsequent 30 years directly in technical sales, and for the past 15 years he has been predominately involved with SEEPEX progressive cavity pumps.

QUESTION: We often hear that progressive cavity pumps are extensively used in the mining industry. What are some of the common applications where these pumps are most suited?

ANSWER:

It’s correct that progressive cavity pumps are very common on mine sites throughout Australia. In fact, this particular market sector would be on par with water/wastewater, as one of the most popular for PC pumps in Australia.

To list in detail the various applications would take up this entire magazine issue, so instead I have summarised the following typical applications and the key benefits of this pump design.

Mine types where progressive cavity pumps are used in Australia:

- Bauxite (also refined alumina)

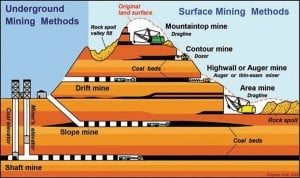

Mining methods.

- Coal

- Copper

- Gold

- Iron ore

- Mineral sands

- Nickel

- Shale oil

- Tin

- Uranium

- Vanadium

- Zinc

Also used by countless suppliers of mining equipment and chemicals for:

- Decanters and centrifuges

- Tunnel drilling equipment

- Flocculants

- Chemical dosing

- Liquid explosives

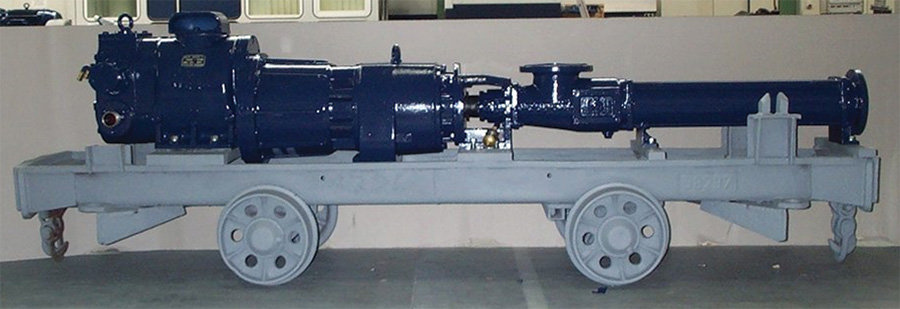

Progressive cavity pump mounted on rail car.

Common applications for progressive cavity pumps in mining:

- Transfer of mineral slurries

Typical mine above and below ground.

- Void back-filling applications

- Dosing of explosives

- Thickener underflow applications

- Centrifuge filling

- Chemical dosing

- Water treatment

- Cake transfer

- Leachate treatment

- Gland water supply

- Sludge feed to dewatering machines

Typical transfer liquids include: polymers, sludges, slurries, grouts, various chemicals, clean and dirty water.

Mine dewatering applications for progressive cavity pumps:

This is probably one of the most common areas where progressive cavity pumps can be seen, usually installed on a transportable skid with collection tanks for incoming water, and generally incorporating some kind of solids separation to partially clean the muddy, high sediment mine water.

The range of progressive cavity pumps used for these applications can be quite long in length, due to the pressure generation required for pumping to the surface from several hundred metres underground.

There are several companies currently who specialise specifically within this application sector and occasionally there can be new design developments which may give significant benefits to the users of this product range.

Keeping oneself abreast of these developments can certainly pay significant dividends to mine operators.

More detailed information on specific design developments can be requested via the contact details at the end of this article.

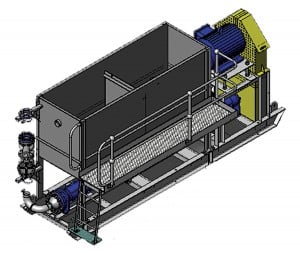

Typical belt-drive PC pump dewatering skid.

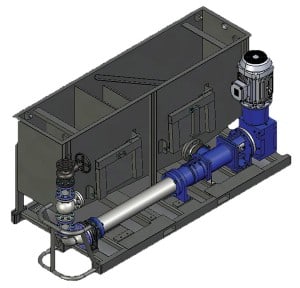

Typical direct-coupled PC pump dewatering skid.

What are the progressive cavity pump benefits:

- Self-priming

- Non-pulsating flow

- Valveless operation and flow control

- Reversible for back-flushing

- Flow proportional to speed

- No day-to-day maintenance required

- Versatile, can be installed horizontally, vertically and virtually any position

- Minimal flow drop against changing pressures

- Ability to handle multi-phase fluids (liquid and gas)

For more information on progressive cavity pumps for the mining industry, please contact SEEPEX Australia on (02) 4355 4500 or [email protected].