Kalium Lakes Limited (KLL) has completed its brine extraction and supply infrastructure for its Beyondie Sulphate of Potash Project (BSOPP), including brine production bores and pump stations achieving “nameplate” flow rates.

KLL CEO, Rudolph van Niekerk, said, “Commissioning of the brine extraction infrastructure at nameplate capacity is a significant and further de-risking milestone for the project.

“It not only validates the mine plan, but also continues to meet pre-production targets while we advance toward first production in the third quarter of next year.”

Overall progress at BSOPP is now 63 per cent complete and importantly the project remains on schedule and within its revised budget.

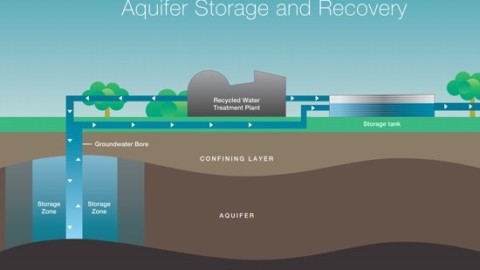

Brine is supplied from the Ten Mile and Sunshine resource locations for the BSOPP, as shown in the image below.

Each of the brine extraction areas includes a series of production bores to extract brine from the paleochannel and sandstone aquifer resources located between 10m and 140m below ground level.

Actual flow rates achieved from commissioning and test pumping matched modelling for the bore field within each of the extraction areas, summarised as follows:

With all trenching work now complete, two trench pump stations are installed at each of the lakes to extract brine from the shallow brine resources contained within those lakes.

These pumps have a combined flow rate in excess of the planned 100 litres per second, with average grades to date of 12,470 mg/L potassium against the mine plan of 8,970 mg/L potassium.

Evaporation pond construction is also progressing on schedule with 61 per cent of all primary ponds now complete.

Kalium Lakes has also mobilised three lining installation contractors, fast-tracking liner installation to achieve the greatest benefit from the high evaporation rates during the upcoming summer period.

With many of the primary ponds already in production, new ponds are added to the process as soon as liner installation for those ponds is completed.