VorTek Instruments Pro-V™ M24 Multivariable Vortex Flowmeter offers accurate and reliable flow metering in a multivariable design. The multivariable design incorporates a high-accuracy velocity sensor, a precision platinum RTD temperature sensor, and a solid-state pressure transducer.

The M24 can deliver volumetric flow, mass flow, temperature, pressure, density and energy (BTU) measurements from a single installed device. This drastically reduces complexity, and equipment and installation costs in comparison to installing multiple standalone instruments to arrive at the same process measurements.

The M24 includes a reduced bore option. The meter’s process connections match the line size but using integrated reducing flanges, the meter body is reduced in diameter. This increases the fluid velocity through the meter. Increasing the velocity in this fashion extends the meter’s measuring range to capture lower flow rates that might otherwise be missed in a full line size meter.

This reduced bore option also shares the same face-to-face dimension as a standard M24 meter for pressure classes up to ANSI 600. So if process conditions change, the meter body size can be changed without any costly piping modifications. This is especially useful in project planning, as it allows for flexibility into the future.

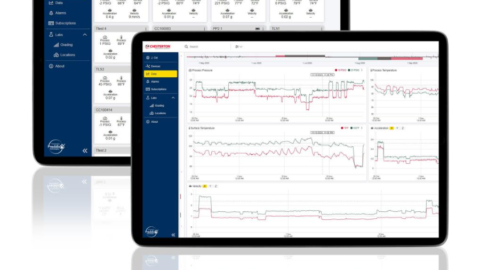

The M24 flowmeter offers an industry-leading variety of communication and power options. In addition to providing traditional communication methods such as analog output signals, the flowmeter also offers the latest and most advanced serial communication options such as BACnet®/IP and Modbus® TCP/IP.

The M24 is the only vortex flowmeter on the market to provide Power over Ethernet (PoE) capabilities. Power over Ethernet functionality delivers power and data through a single ethernet cable. Both simplifying installation and reducing installation costs.

This partner content was brought to you by AMS Instrumentation & Calibration. For further information, contact AMS Instrumentation & Calibration on 03-9017 8225, via e-mail: [email protected] or visit its website at www.ams-ic.com.au.