The pump industry relies on expertise from a large and varied range of specialists, from experts in particular pump types to those with an intimate understanding of pump reliability; and from researchers who delve into the particulars of pump curves to experts in pump efficiency. To draw upon the wealth of expert knowledge the Australian pump industry has to offer, Pump Industry has established a panel of experts to answer all your pumping questions.

This edition of Ask an Expert will look at progressive cavity pumps in oil and gas applications along with special designs to comply with API standards.

Q: What makes progressive cavity pumps so well suited for oil and gas applications, and where are they most often utilised?

A semi-submersible pump that can be installed on a drum.

A: Progressive cavity (PC) pumps are positive displacement pumps that handle fluids gently with only minimal shear or turbulence.

They are suitable for fluids with very high viscosities and the highest solids content, even large or abrasive particles. They can deliver high pressure of 48 bar or more.

Even high vapour pressure (low NPSH) or multiphase fluids are not a problem. With their linear curve and minimal pulsation, they are also suitable for dosing applications.

In the oil and gas industry PC pumps are often used to convey sludge or oily water, or in situations where light hydrocarbons raise the vapour pressure to a level where other pump types would cavitate.

PC pump manufacturers offer a wide range of products for this industry, from dosing and open hopper pumps to semi-submersible pumps or package solutions that allow for automatic control.

One strength of PC pumps is their vertical semi-submersed installation on a drum. Open/closed drain drums or flare knockout drums are other frequent applications.

Q: How do these pumps meet the stringent requirements of American Petroleum Institute (API) 676 standards?

A: Since PC pumps were originally used in wastewater treatment plants, their design and production are optimised for this market. They can also be used in petrochemical applications, albeit the much higher demands are a challenge.

The modifications and upgrades necessary to adapt standard PC pumps for use in the petrochemical industry has a dramatic effect on both price and lead time. The most customisation is required for the casing design and shaft seals.

Among other criteria, the casing design needs to have fully ASME compliant flanges, higher nozzle loads, flanged casing drain and a design pressure (MACP) able to achieve higher containment pressure for upset conditions. Shaft seals also need to be engineered to meet API 682 requirements. A few PC pump manufacturers have risen to the challenge.

Q: What is the best option when purchasing a PC pump for oil and gas applications?

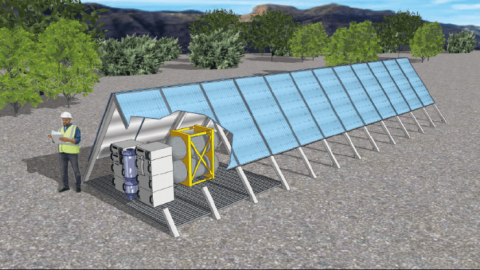

A: To provide project engineers with smooth sailing and purchasers with favourable prices and lead time, some PC manufacturers have designed and produced API 676 conforming pumps.

They fulfil the casing and shaft seal requirements, while being built with materials suitable for highly corrosive and harsh environments. PC manufacturers use their many years of experience to create and produce solutions that help customers save time and money.

A fully API 676 compliant PC pump.

About the author

About the author

Peter Vila, Managing Director of SEEPEX Australia, is a progressive cavity pump expert. He has been involved with pumps for over 40 years. Peter spent the first five years repairing pumps and the following 35 years in technical sales, 20 of which have been with SEEPEX progressive cavity pumps.

For more information on progressive cavity pumps, please contact SEEPEX Australia on (02) 4355 4500 or at [email protected]