By Paul White, Team Leader – Program Management and Technical Support, Sydney Water

Sydney Water operates and maintains 680 Sewerage Pumping Stations (SPS) and 164 Water Pumping Stations (WPS) in the Sydney, Blue Mountains and Illawarra areas. It is one of the world’s largest operator of pumping stations, reflecting the hilly terrain of the Sydney Basin, particularly on the coastline and rivers.

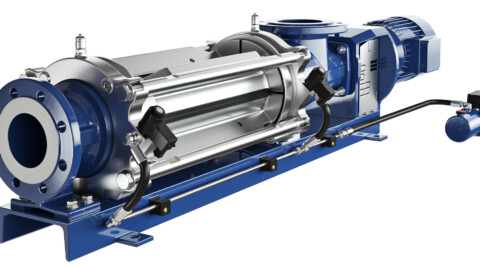

The early types of pumping stations were mainly of ‘conventional’ type (horizontal or vertical centrifugal pumps with coupled motors, or dry submersible-type pumps) housed in a dry well with an outer wet well for a SPS or on a platform next to a reservoir for a WPS. Apart from the conventional type pumping stations there are also different types of SPS’s. There was SPS ‘ejector’ types using compressed air to push sewage up the SPS pressure main, but these became obsolete and all have been replaced. Sydney Water was the first in Australia to use ’vacuum’ SPS’s in low, flat, high-water table areas that uses a vacuum to suck sewage from small pits located near houses and taken to the SPS. However, the majority of current SPS’s are of a ‘submersible’ type, using pumps located within a circular wet well to pump the sewage up the pressure main. The size of these pumping stations varies enormously from small of only a few litres per second pumped to large stations pumping many hundreds of litres per second.

Typically, an SPS has two pumps (one duty and one standby) whilst a WPS will have two to four pumps (one to three duty and the remainder standby). The stations are unmanned and can be in remote locations. The pumps are the most important equipment of the pumping station, with its function to pump the water or sewage from a low collection point to a higher discharge point like a water reservoir or a sewerage trunk main. The stations have in normal circumstances redundancy in that if the duty pump fails then the standby pump will automatically takeover the pumping duty. Failure is detected using IICATS (a 24/7 telemetry alarm and control system). If the standby pump does not start (due to a fault, is already offline for repairs, there is supply power failure) then there is a period of detention time. Detention time is the capacity of the wet well and incoming sewerage main matched against the sewage inflow (inflow varies considerably at different times of the day) for a SPS. For a WPS it is the water reservoir capacity matched against customer water consumption. Detention time is the period before sewage overflow or loss of water supply will occur to allow a breakdown response crew to attend the pump failure and effect repair.

Sydney Water has installed at a large number of pumping stations additional safeguards such as emergency storage tanks to greatly increase detention time, on-site gas powered emergency bypass pumps, on-site electrical generators or dual power supplies. If the pump fault repairs are likely to exceed available detention time, and there are no additional safeguards, then Sydney Water declares an Incident and implements the most appropriate contingency action to avoid sewage overflow or a loss of water supply.

There are different types of contingency action for pump failures and each pumping station needs to be assessed for the most suitable action to be implemented. All the pumping stations in Sydney Water have site specific contingency plans that contain relevant technical details (pump head, inflow and required pumped flow rate, pump motor KW rating, pump type/model number and relevant drawings), if bypass pump fittings are installed, the nominated tanker collection/discharge points, suitability for mobile generator connection or a packaged diesel pump. The Incident Site Manager selects the most appropriate contingency action based on the contingency plan and experience.

Previously the most common contingency action for failed SPS pumps or even power failures was using tankers. Similar in size to a large petrol tanker (about 22,000 litres capacity), these tankers with its on-board pump are used to suck up the sewage from a collection point and then transport it to another sewerage system area for controlled discharge. Unfortunately this has significant limitations, such as sometimes the small on-board tanker pump is unable to overcome static head (generally greater than 5 metres) to lift the sewage for collection. Or due to the large SPS inflow too many tankers are required that create a logistical problem. A mobile diesel pump can be brought in to provide better lifting capability, but again there remains some limitations on ability to lift the sewage (greater than 10 metres). A submersible pump if able to be brought in and temporarily installed within the SPS wet well is a better proposition to feed the tankers as it has no lift limitations. Better again and now the most preferred contingency action, is to have a temporary installed submersible pump having its discharge pipe connected to a purpose-built plate installed on the SPS or WPS pressure main. This bypass pump fitting plate has a camlock connector, reflux and stop valves welded in-line and attaches to the pressure main, typically above the pressure main reflux valve. This action can provide bypass pump indefinitely with minimal ongoing monitoring, unlike using tankers. Tankers cannot be used for WPS failures, nor bypass pumps and local rezoning of the water supply network by operators can provide water to affected customers.

It remains that the easiest, least expensive, and most reliable method to ensure pumping ability of the pumps at a pumping station is to perform appropriate preventative maintenance (particularly for large pumps), monitor operating performance (to detect partial chokes, noisy or hot bearings, excessive gland seal leaks) and to effect speedy repairs to reduce the out of service time.

For power failures, a suitable mobile generator can be used at the pumping station site with a quick connection box installed at most pumping station sites. It is important to consider both start-up current and running current requirements when selecting the mobile generator.

From fairly humble beginnings of locating spare bypass pumps and piping at various sites in its area of operation, Sydney Water now has a much more sophisticated centralised contingency and bypass pump equipment storage at its Potts Hill Centralised Warehouse. There are various sized mobile packaged pump units, starters and generators on trailers complete with correct-sized piping and pipe joiners. It is general protocol to only use these units for a few days when needed in an Incident and then returned to the Warehouse to ensure availability. Equipment hire of this equipment is used if there is need for this type of equipment greater than a few days at the sites. There are also maintained bypass pumps, almost all of the submersible type, of various sizes and pumping duties to match the variances in Sydney Water pumping stations. These are arranged in a numbered grid pattern to facilitate easy identification, enough space for pump movement and to enable regular preventative maintenance. The aim is to ensure rapid access, easy identification, establish equipment suitability and then service reliability once installed in an Incident.

As can be seen, there is much preparation to undertake a swift continuation of the pumping function at our pumping stations when faults develop to ensure continuing customer service and to protect the environment.