Following on from our first article about impeller trimming in the last issue of Pump Industry, this article will continue to outline things can happen when the impeller vane diameter is reduced. In part one, we looked at changes in performance and NPSHR. We will now look at mechanical impacts that can occur with impeller trimming.

Mechanical impacts

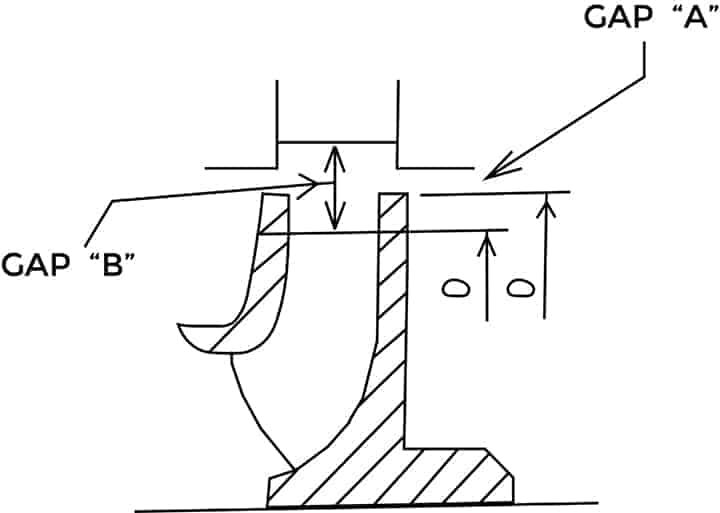

- Excessive shroud to casing clearance (Gap “A”) and the resultant recirculation to the low-pressure side of the pump will produce “eddy flows” around the impeller, causing low frequency axial vibrations that can translate to mechanical seal problems. This can be a real concern in large pumps with powers over 200kW or pumps pumping heads in excess 200m

- For many years pump people have been machining the vane tips to reduce the vane passing frequency vibrations (Gap “B”) while carefully maintaining Gap “A”. The pulsating forces acting on the impeller can be reduced by 80 per cent to 85 per cent by increasing Gap “B” from one per cent to six per cent

- For impeller diameters up to 355mm, Gap “B” should be at least four per cent of the impeller diameter to prevent “vane passing syndrome cavitation” problems. For impeller diameters above 355mm, Gap “B” should be at least six per cent of the impeller diameter to prevent this type of cavitation. This type of cavitation damage is caused when the outside diameter of the impeller passes too close to the pump cutwater. The velocity of the liquid increases as it flows through this small passage, lowering the fluid pressure and causing local vapourisation. The bubbles then collapse at the higher pressure just beyond the cutwater. This is where volute damage occurs. Unless damage has penetrated to the outside of the volute, a flashlight and mirror will most likely be required to inspect the damage. The damage is limited to the centre of the impeller vane. If it’s a closed impeller, the damage will not extend into the shrouds

- Although both the vanes and shrouds are often cut in end suction, volute-type centrifugal pumps, it is not a good idea to do this in double suction designs. With these types of pumps, you can reduce the vane diameters, but the shrouds should remain untouched

- Structural strength is a consideration when deciding how much to reduce the vane diameter in double ended pumps because you could leave too much unsupported shroud. Some manufacturers recommend an oblique cut that will improve the vane exit flow and add some strength to the shrouds

- Machining a radius where the trimmed vane meets the shroud is another good idea to add strength to the assembly. Square corners are never a good idea

- Gap “A” describes the clearance between the impeller shrouds to the volute or casing

- Gap “B” describes the clearance between the impeller vanes and the casing or volute

- “D” describes the diameters of the vanes and shrouds

Article courtesy of Kelair Pumps Australia “When Pump Knowledge Matters”. Phone: 1300 789 466 or visit www.kelairpumps.com.au.