Reduction of sludge treatment costs is a challenge at sludge treatment plants across Australia. Engineers from seepex recently worked with a team from UK water authority Severn Tren to improve the performance of their plant, highlighting the role their pumps can play in improving sludge treatment plant performance around the world.

The engineers from seepex and Severn Trent came together at the utility’s sludge thickening plant in Packington, England. This site, near the town of Ashby de la Zouch, treats sewage from a population of 28,000, so system reliability is crucial to both Severn Trent and the local population.

The situation

The sludge thickening plant had been experiencing excessive downtime for some time and system failures were causing poor performance of the sludge discharge pump. Breakdowns were causing frequent pump repairs, with associated maintenance costs and also the cost of sludge movement on site by tankers.

As the problems in the process were becoming more regular and pump replacement failed to solve them, a new approach was needed. seepex were asked to look at the whole system with Severn Trent engineers and to use their combined experience in sludge pumping to diagnose the causes of downtime. The investigation found not one problem but a series of small issues which, when combined, led to poor overall performance of the sludge thickening plant. Understanding the requirements of pump performance within the system was crucial to the subsequent proposal to solve the issues and restore sludge thickening performance.

The solution

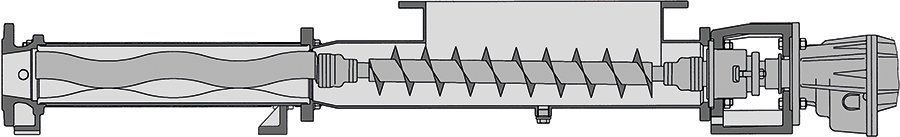

seepex offered an open hopper pump from the BT range with a larger capacity than, and different design to, the existing pump. The discharge chute from the thickening units was adapted to feed directly into the pump hopper and the integral auger screw pushes the sludge into the pumping elements of rotor and stator. This improved configuration handles sludges of varying consistency from the thickening plant.

In addition, the control system was automated to use ultrasonic level control in order to vary the pump speed (by use of a VSD), and balance the discharge rate to the thickener output, thus eliminating high level problems and subsequent shutdown of the equipment.

The discharge pipework was changed to a surface mounted installation with increased diameter. Access and inspection are easy and should post pump blockages occur, removal of these will be straightforward.

The benefit

The reliability and performance of the sludge thickening system has been improved by the ability of the pump to handle sludges of varying thickness and the automatic control of pump speed linked to level controls. Downtime and maintenance time and costs have been reduced, and associated sludge tankering costs removed.

Andrew Perry of Severn Trent said, “To date we have not incurred any tankering costs as a result of this issue and the unit has not stopped at all since the installation. Our aim is to resolve all problems in such a professional manner.”

Key facts

• Pump type – Range BT

• Open hopper pump with auger feed screw

• Ultrasonic level control linked to pump speed

• Quick maintenance

• Improved reliability

• Significant cost savings

• Reduced downtime

• Reduced maintenance costs

• Reduced sludge disposal costs