SAER’s contribution to sustainable development stands out in its commitments to design efficient and easy-to-maintain products.

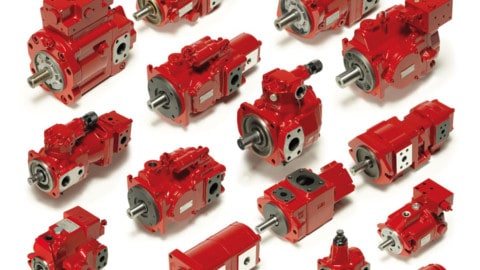

Focusing on the range of split casing pumps, SAER’s SKD series includes more than 80 models (flows up to 4,500m³/flow and 300m of head, from DN80 to DN500).

In addition to the usual advantages, thanks to the axially split casing construction – providing ease of installation, robustness and possibility of maintenance of the rotating parts without removing the pump from the system – SAER SKD pumps are standardly equipped with: double volute design to minimise radial thrust on bearings (bearings rating life > 2×10⁵ hours), eliminating the radial stresses acting on the rotor and reducing vibrations and noises.

Plus, the double wear ring protects the casing and the impeller. The impeller, body and cover are protected from reciprocal wear, increasing the machine operating time, and reducing time and cost of maintenance.

A peculiarity of the range is the wide choice of models and configurations available. Indeed, the SKD series can be supplied both for horizontal or vertical installations, plus the pump may be produced with several combination of materials (cast iron, ductile iron, bronze, stainless steel 316 and super duplex) and types of seals (gland packing, mechanical seal, cartridge, etc.). The range can be supplied as complete set with motor or bareshaft, or as complete group without motor.

100 per cent of the production is tested in SAER facilities, where any trial can be performed according to the given requests, and main approvals can be directly obtained there.

This Sponsored Editorial is brought to you by SAER Elettropompe S.p.A. For more information, visit https://www.saerelettropompe.com/en/home.