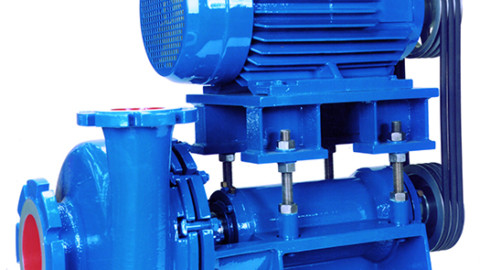

A copper mine in Tasmania was looking to reduce pump failures, which were occurring frequently and at a high cost. The pumps on this site are located 2.4 kilometres underground which means pump maintenance can be both difficult and expensive. The pumps operate at a high speed to develop the high pressures levels required to dewater the mine.

This site was experiencing regular pump failures with legacy 4/3DD-AH pumps. Bearing assemblies were running at extremely hot temperatures at an average of 105°C and had a short life of only 2 to 3 months. Excessive greasing was used in an effort to reduce the temperature, which was potentially compounding the problem. These pumps were also consuming excessive quantities of fresh water to lubricate the gland packing, at approximately 30 litres, per minute for each pump.

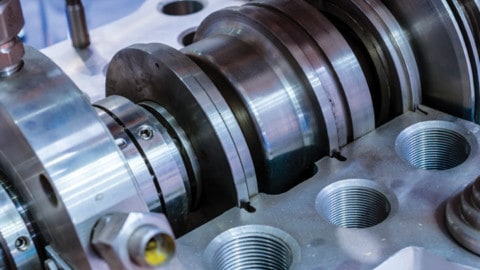

KETO worked with the site to solve these issues and recommended a K-IBA™ to be installed in the existing legacy pump. These heavy duty bearing assemblies are designed to pump at high pressures and are interchangeable with the legacy bearing assemblies which were previously installed.

To reduce the water usage, a K-ISS™ seal was installed in the legacy pump. K-ISS™ seals can cope with high suction pressures while remaining leak free. A constant flow control valve in the K-ISS™ seals automatically compensates against changes in suction pressure and wet end wear.

Since the installation of the pump upgrades, the bearing assembly running temperature has reduced from 105°C to 65°C. It is now running at a normal touchable temperature at both ends. This has removed the need for excessive greasing. The bearing assembly has been running for 12 months, that is, 4 times the average life of the legacy bearing assembly.

The K-ISS™ seal has had a significant impact on water usage. The water usage on the pumps has reduced from 30 litres per minute to 6 litres per minute, a saving of over 12 million litres of water per pump per annum.

KETO are now working on the site to install the same arrangements on the bank of 6 pumps, and with other site installations to increase bearing life, minimise greasing requirements, and reduce water consumption.

The Tasmanian copper mine achieved savings of over $21,000 per annum on spare parts without even considering flush water and maintenance savings.