Ted Beesley began his career as an accountant before joining his family’s pump company as an accountant/junior sales assistant. Since then Ted has had a long and successful career in pumps, working with companies such as Brown Brothers and Engineered Products Group (EPG), as well as running his own company, Pumpserv. Here, Ted reflects on his career in the industry and how the industry has changed.

Ted Beesley

A family in pumps

We originally came from Adelaide where dad was Manager of FR Mayfield electrical contractors. He took on a Kelly & Lewis agency to obtain work such as pumping stations on Mannum-Adelaide and Mannum-Whyalla pipelines.

Kelly & Lewis poached dad from Mayfield in late 1960 and we moved to Sydney so dad could take up his role as NSW Manager. He left two years later and got involved with Sykes Pumps while manager for Coates Hire. He tried to convince Coates to start hiring out Sykes pumps but they weren’t interested, so he started KAB Projects.

From accounting to pumps

I first joined the pump industry in September 1968. Originally, I studied accountancy at North Sydney Tech College. I worked for a chartered accountancy company for two years and as accountant to a plywood company.

At 21, I was drafted into the army for National Service. I was fortunate to attend Officer Training School at Scheyville and graduated as a Second Lieutenant. I was posted as Stores Officer to 133 Signal Squadron at Kingswood in Western Sydney. This afforded me very good management experience as I was 2IC of the camp.

After two years national service, the plywood company had changed hands so my father suggested I work for the family pump company, KAB Projects. I started there as accountant/junior sales. Our initial main products were Worthington pumps, Forrer sewage pumps, Grundfos pumps, and Sykes pumps.

My father left KAB Projects a year later after attending a board meeting at Sykes Pumps UK. He returned to Australia as a Director of Sykes UK with the power to start Sykes Australia and teach Malcolm Cramb to take over as Manager once the business reached

$3 million yearly turnover. This took three years.

During those three years I did almost everything at KAB Projects, and each night sent a bag of questions home with mum, for dad, and she would bring back answers the next day. It was virtually a pump sales course by correspondence. I wished I could have been able to plug a computer into dad’s brain and download his pump knowledge.

An early photo of Ted with his daughter Heidi, wife Melanie and son Lincoln.

Growing the market in New South Wales

I was instrumental in getting Grundfos established in New South Wales as dad knew Ray Pank in Adelaide very well from their electrical days. We were sole New South Wales distributors for about 10 years then received a commission for all units sold in New South Wales for a few years more.

Our factory was in Hornsby but we installed all over New South Wales, Queensland and Victoria. We started importing, with customs duty of 25 per cent (10 per cent developing countries), from Sakuragawa, Kirloskar, Vogel, Emu, SEEPEX, Roto, Hermetic-Lederle, Pompe-FBM, Apollo, Hidrostal, Gorator and more. This period saw intense training in pump application and sales.

Starting a business

In 1979, KAB Projects went into receivership so I bought the Sakuragawa Agency with assistance from contacts in Newcastle and traded on as Kabpro Sales. Part of the deal was I had to spend time in Newcastle and teach them about pumps.

In 1985, I sold Kabpro Sales to Malcolm Thompson Pumps and stayed on as NSW Manager and Sakuragawa Product Manager for nine years. This was MTP’s first venture outside of Western Australia.

We were essentially an importer of Varisco and Sakuragawa, but were also responsible for about 20 per cent of all Grundfos sales in New South Wales. We had a team of five external and four internal sales staff plus six in workshop and four in office.

Malcolm Thompson brought in a new management team in 1994 and although they wanted me to stay I decided it was time to move on. So I returned to Pumpserv, a company started years previously by myself and Ron Maher, but by this time was owned by myself and my wife Melanie.

This was the perfect platform for continuance, as many people were coming to me for pump assistance, and it just grew. We tried to get a Grundfos account but they would not grant one as their other distributors knew too many customers would flock back to me. I then approached Brown Brothers and started selling Lowara with good success.

A hands-on pump career

After three years I went back into the larger pump world as NSW Manager of Engineered Products Group (EPG). Melanie and our son Lincoln took over running Pumpserv.

Two years at EPG taught me I needed a more hands-on pump life, as looking after the four divisions at EPG left little time for customer contact, it was constant paperwork.

I approached John Inkster at Brown Brothers in June 2000 and told him he needed me. I worked as NSW State Manager for six years, and we had great success expanding the Lowara/Goulds/Hydrovar products throughout New South Wales.

In April 2006, I returned to manage Pumpserv, where my wife and son had done a great job, but Melanie wanted a break.

During my absence they had commenced stainless steel base, manifold and shroud manufacturing, and this has continued to grow to the point where we are manufacturing for Franklin, Xylem, Aline, KSB, Hydro Innovations, DP Pumps, Grundfos, Skyline, Doyles, BKB, GT Water, and more.

A lifetime of contacts

The pump industry has been very good to me, and has given me lifetime contacts. I really enjoy what I do, particularly more so now, as people come to me for answers. The industry has also given me contacts overseas which have helped greatly.

I have worked with pretty much every pump company in Australia over the years and many overseas companies. They have all, in some way, contributed to my life. Without a doubt, my biggest mentor was my father. He provided me with a lot of pump knowledge, but more importantly, business ethics. He was what I now describe as one of the gentlemen of the pump industry.

Ted and his wife Melanie in Venice.

A changing industry

When I started in the pump industry it was essentially only selling Australian made products, but now it is virtually all imported, which is a great shame as we no longer have the engineering expertise that was so valuable to my learning.

The most memorable moment of my career was my first business trip overseas in 1978. It really opened my eyes as to what was available in the world. I was away for seven weeks and visited Japan, Europe, England and India. Since then, many trips (including Japan every two years) have consolidated this view that we need more knowledge.

The most significant development I have seen is the loss of Australian manufacturing, but now, more importantly, the loss of sufficiently trained people in the industry. I’ve always sent new staff to training schools, where possible, and feel that doing this would benefit more people. Unfortunately, some larger multinationals are reverting to salespeople in a one-off location and these people do not necessarily fully understand what they are selling.

It’s not just the pump industry which is doing this, but the personal contact between salesman and customer is being lost. One of my major complaints is when I ring a company for some quick answers only to be told everyone is in a meeting and someone will ring back later.

I’m still heavily involved in the pump industry. Pumpserv has a good business in stainless steel base, manifold and system building, plus we re-sell many brands of pumps to irrigation, motor rewinders, and building services, as well as service work in golf courses, and power stations. Our claim to fame is the written knowledge we have of a vast range of pumping equipment, which is why people come to us for answers. We also import a range of air blowers (Hiblow from TTC Japan) for the septic tank and aquarium industries.

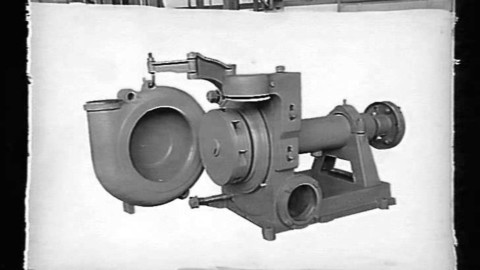

Three typical build jobs from Pumpserv.

Imparting knowledge

The biggest challenge for the pump industry is to get younger people involved. To do this some of us need to impart more knowledge so the industry can thrive. These young people need to absorb any knowledge on offer and attend meetings, training, trade shows, etc. But the best learning by far is at the site of the pump.

One of my greatest pleasures in the pump industry is to see people who have worked for me advance themselves. I know that a small company is a stepping stone for many people and I am only too happy to help people advance. I have been criticised in the past for helping staff find a job stepping up the ladder, but I think it’s wrong not to help. These people have always appreciated it and helped me in the future. One thing I tell everybody who is looking for advancement is do not burn bridges behind you.

From pumps to golf

My wife Melanie and I met before the National Service, but we got engaged and married while I was in the Army. We have been happily married for 49 years and have two children, Lincoln and Heidi.

Melanie and I love travelling and are also keen golfers. We play regularly and are members of Avondale Golf Club. I played rugby for 21 years (from ages 16-37) for Lindfield Rugby Club and am now a life member of NSW Waratahs, so we also go to quite a few major rugby matches.

We have also lived in our current house for 45 years and the garden is a credit to Melanie, while I enjoy the role of labouring assistant with mowing duties.

Typical build job from Pumpserv.