by Greg James, Hydro Australia

Rebuilding a typical boiler feed pump cartridge and returning the running clearances to specification is a critical process for effective and efficient plant operation. The cost to rebuild a cartridge – supply new mechanical seals, bearings and consumables, the lost production, down time and the labour costs – is a significant investment.

After rebuilding a cartridge and returning all operating clearances to specification, the good work can be greatly affected by installing the cartridge into a distorted barrel and/or discharge head combination.

When changing over a feed pump cartridge, it is every bit as important to check the barrel and discharge head for concentricity and parallelism, and to check the condition of the gasket mating surfaces.

A typical segmented ring or split inner volute barrel pump design will have two, three, four or more mating/gasket surfaces, all requiring a consistent quality surface finish to ensure the gaskets perform as designed and to ensure that the cartridge remains square in every aspect once installed.

After years of service and thermal cycling on hundreds of occasions, the barrel and/or discharge head can stress relieve, creating out of square mating surfaces.

In most instances this will need to be checked only once, however, if there are signs of gasket leakage it is recommended to check all surfaces at each cartridge change.

On site in situ barrel machining

On site in situ barrel machining

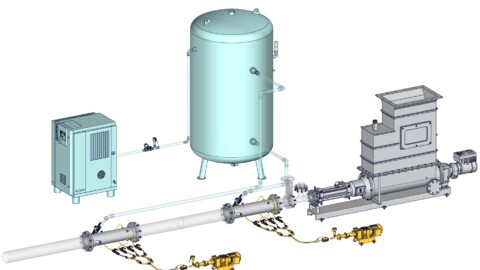

Hydro Australia have the experience, knowledge and all the required equipment to perform a cartridge change over, barrel concentricity check and if required, to machine the barrel using our on site in situ machine system to return the barrel to specification.

Hydro Australia have built a test rig, enabling duplication of the barrel configuration in the workshop.

This will ensure that all the correct equipment is set up and ready to go when arriving at site, having checked every aspect for correct sizes and tight configurations.

This partner content is brought to you by Hydro Australia. For more information, visit www.hydroaustralia.com.au.