Dealing with by-products in the food industry is a challenge virtually all manufacturers face. A number of companies are discovering the benefits of using pump systems to process and remove waste from high care operation areas.

Most food factories produce by-products, particularly if their business is that of primary processing, converting raw materials into finished products. Processors need to remove waste by-products from their production areas as efficiently and hygienically as possible, incurring the lowest cost and maximising any potential revenue to be gained.

Traditionally there have been different removal methods used, such as:

- SEEPEX open hopper pumps and waste removal systems

- Manual removal using tote bins

- Blown air systems and vacuum systems

- Flumes using water as a transport medium.

Many processors use combinations of these, often determined by plant layout, previous experience and regulatory demands. With the exception of the SEEPEX pump systems however, they all incur high running costs in the form of manual labour, energy use or water treatment.

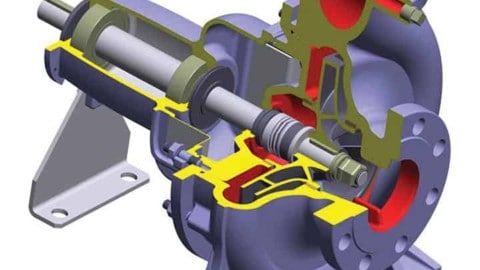

SEEPEX systems all incorporate a progressive cavity pump, capable of pumping both high and low viscosity products, with and without solids. For most applications a patented design pump which can chop and pump food waste with up to 40 per cent ds, without added water is used. The open hopper BTM range pump has an auger feed into fixed and rotating knives which can chop most products.

The design means that any discarded products, defective raw materials, trimmings and rejects (including overrun), can be handled in a single system, enabling pre-treatment and source segregation of waste and by-products, even when they vary greatly in solids contents and viscosity. There are now more biogas plants in operation, many of which need food waste to produce energy and the SEEPEX pump produces an ideal feedstock for biogas operations: a liquid slurry that contains no contamination.

The pumps can handle whole cabbages and wet coleslaw, whole raw potatoes and mashed potatoes, whole chickens and chicken trimmings, all in a single multipurpose unit. Efficient and hygienic removal from high care and low risk areas is ensured, providing food processors with the least cost removal together with highest residual value of by-products as demonstrated by the following case studies.

Vegetable waste removal from high care areas

A fresh food company wanted to remove tote bin traffic from high care to low risk areas, due to the subsequent return of the tote bins proving a hygiene issue. The volume of waste from vegetable preparation was high, and in comparison to the weight, transport costs for removal were high. The factory was expanding to fulfill increased demand for ready prepared vegetables and SEEPEX installed a hygienic BTM open hopper pump to chop and remove the waste directly from preparation areas.

This company now has a low volume by-product removed directly from production areas without the need for manual movement of tote bins.

Other fruit processors have installed SEEPEX pumps with auger feeds into vertically mounted grinders to handle difficult waste from stone fruits such as mango and peaches. The use of these removes all waste from processing areas, producing a slurry which is then sent to biogas plants for energy generation.

Chicken and bio-security

Chicken processors have to segregate those birds which are dead on arrival at processing plants, together with any diseased birds found by subsequent inspection. Regulations typically require that these have to be cut and dyed before segregation for rendering or other further processing before disposal. The SEEPEX BTM pump takes whole chickens and then chops them with the addition of dye before pumping them in an enclosed system to the disposal area. This gives customers complete confidence with demonstrated compliance.

A SEEPEX BTM open hopper pump, showing detail of rotating and fixed knives.

Poultry by-products

SEEPEX have provided a different system for one poultry plant, to enable entrails to be chopped into a suitable pet food raw material. This uses an auger feed to a vertical macerator followed by a pump. The entrails are removed directly from the main processing area as slurry, which is then frozen for pet food use.

Mixed ready meal waste

Another food company had problems with mixed consistency food waste which was too liquid for solid waste and not liquid enough for tanker transport. SEEPEX installed a BTM open hopper pump with an additional macerator to ensure smooth slurry was produced from the mixed ready meal waste. This high energy value waste is now transported in road tankers to a nearby biogas plant, saving the food company considerable transport and waste disposal costs.

SEEPEX pump, macerator and auger combination for processing poultry by-products.

SEEPEX pumps and systems provide a flexible means of removing waste and by-products from food and beverage processing areas without the use of excess energy or added water. For more information, or to request a free site survey to establish if we can help you, please contact SEEPEX Australia on 02 4355 4500 or [email protected].