Principles of operation

The term peristaltic pump is applied to various ranges known as hose or tube pumps. Although there are specific differences between hoses and tubing, the terms hose and tube are interchangeable in this article.

Generally, hose pumps have a large wall thickness, polyamide reinforcing layers and are capable of handling differential pressure up to 15 bars. Tubing has a smaller wall thickness and tube pumps are generally capable of differential pressures up to four bars.

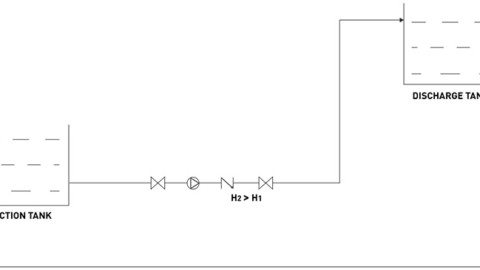

Peristaltic pumps are self-priming rotary positive displacement pumps that operate on the peristaltic principle. The pump consists of three major parts: hose or tubing, housing and rotor. The hose is placed in the tubing bed between the rotor and the housing. The rotor has a number of “rollers” or “shoes” attached to the external circumference.

These move across the hose where it is occluded (squeezed), pushing the fluid. The hose behind the shoe or roller recovers its shape, creating a vacuum and drawing fluid in behind it.

Liquid is trapped between the rollers or shoes specific to the ID of the hose and the geometry of the rotor. Flow rate is determined by multiplying speed (rpm) by the volume of the trapped liquid. The volume moved is consistent, even under a wide range of viscosities or density. The flow rate is directly proportional to the gearbox speed (rpm).

Benefits of peristaltic pumps

- Available in a range of sizes that provide various flow rates

- Will handle fragile fluids with little wear

- Since only the inside of the hose and hose inserts are in contact with the fluid, they can be processed without the devastating damage experienced by other pumping technologies

- Hoses are constructed of natural rubber, NBR, EPDM, Hypalon, FKM

- Provide high levels of volumetric accuracy for sampling and metering applications

- Ability to pass solids in the material being pumped, 20 per cent of hose ID

- Dry run capability allows tank and line stripping

- Sealless design eliminates leaks, contamination and wear problems associated with difficult to seal products

- Self-priming up to 9.8m at sea level on water

- Reversible operation allows pumping in both directions

- Durable construction of ductile iron and steel construction allows higher discharge pressures up to 15 bars

- Low maintenance requirements of the hose and shoes

Article courtesy of Kelair Pumps Australia “When Pump Knowledge Matters”. Phone: 1300 789 466 or visit www.kelairpumps.com.au.