Imbalances within a network do not often result in positive outcomes. Unsurprisingly the same applies to rotating machinery, pumps and fans, where vibration caused by imbalance can become a significant engineering problem. For over 20 years, Precision Balancing has been helping its clients overcome these problems, enabling them to quickly get their machinery back online.

What causes an imbalance?

If the centre of mass within a rotating device does not coincide with the centre of rotation, the mass centre axis will be different to its running centre axis. Vibration will then result, gradually causing damage to bearings, followed by malfunction or breakdown of the machine.

When it comes to longevity and life-expectancy of a pump, fan or rotating machine, it is therefore crucial to ensure balance within the system.

Vibration is primarily the result of imbalance created by minor imperfections within the rotating component, or non-symmetrical elements commonly found in newly machined parts. It is then the centrifugal force due to the unbalance which causes the device to vibrate.

How Precision Balancing solves the problem

Precision Balancing uses industrial balancing and vibration analysis on rotating machinery, enabling early detection of faults before breakdown. Mass distribution of a product is checked and adjusted in order to ensure that the forces on the bearings are created equal. As the mass centre line approaches the true axis, weight is either removed or added to the unit so as to make the two centres coincide. Such analysis also helps facilities to greatly reduce maintenance costs.

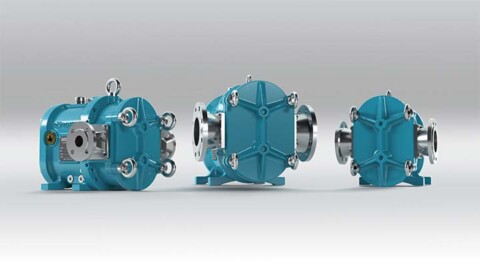

The wide capabilities of Precision Balancing mean that the company can balance a vast range of items both within their workshop or on-site. No object is too large or too delicate for their expertise, with specialisations covering objects as diverse as drums, automotive equipment, centrifuges and couplings.

Why balance?

Apart from improving overall safety of your pumps, fans or rotating machinery, balancing your equipment lengthens the service life of the product. This aids in reducing the chances of downtime or machine failure. Performance of equipment is also enhanced, which naturally saves on time and money. Bearing load is reduced and so too is noise, resulting in a more highly efficient, quiet and reliable machine.

Proudly Australian owned

Precision Balancing is an Australian owned and operated company based in Melbourne Australia, offering in-house and on site dynamic balancing and vibration analysis services since 1989. Precision Balancing is owned and operated by qualified Mechanical Engineers who are members of the Australian Institution of Engineers. As a team, Precision Balancing has years of experience in Mechanical Engineering and Industrial Balancing, as well as other related industries that require this specialised range of services.