By Keith Sanders, PIA Councillor and Life Member

In an age when we are all used to tweets and acronyms, we need to achieve some uniform understandings about what is happening in the global pump market to meet the challenges of climate change and the aim to reduce greenhouse gases.

Going back 50 years, it was common for users of large pumps in Australia to pay close attention to the “Best Efficiency Point” (BEP) and very often pumps were designed from first principles to achieve the highest possible efficiency for a nominated duty flow and head. Scaling from existing hydraulic designs and an awareness of the impact of specific speed on efficiency resulted in some excellent pumps being installed on large water supply and sewage projects, in coal-fired power stations and in major industrial complexes that were designed, manufactured and commissioned by Australian pump manufacturers.

Companies like Kelly & Lewis, Thompsons and Industrial Engineering had large technical departments, who could design the optimum pump impeller and casing configuration to provide the client with pumps that had the minimum operating cost by reducing the demand for power, and maximum life expectancy by minimising vibration and recirculation etc. Pump tenders were often awarded based on a capitalised cost analysis, and pumps made in Australia – while relatively high in manufacturing cost – were ideally suited to the application the client specified.

As technologies changed over time and with the introduction of variable speed drives at lower cost, this has changed the industry. Pumps are no longer designed to meet individual client specifications and are more typically selected from existing ranges of product, developed to achieve a sensible balance between manufacturing cost, product interchangeability and operating reliability.

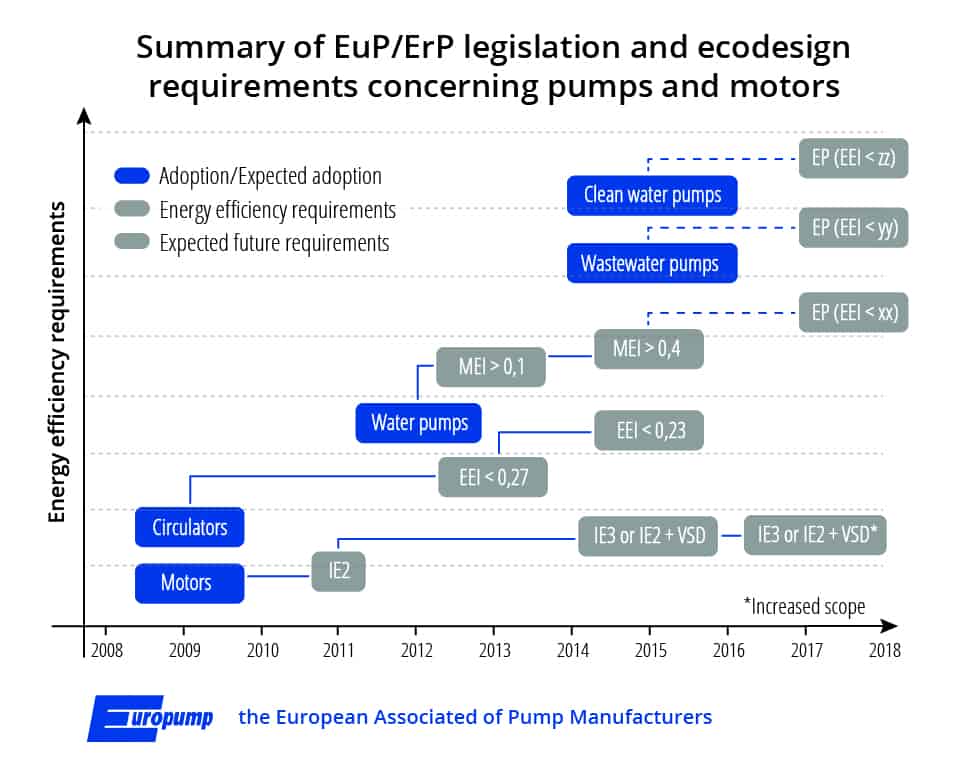

Recognising that a significant amount of electrical power is consumed driving pumping equipment, for at least 10 years, legislators in Europe and the US have been endeavouring to come up with a common approach to defining the efficiency of pumps in a variety of executions that are supplied into the market. The program started with relatively small standard products, like circulators in domestic applications and this has resulted in significant progress being achieved at that end of the scale. On this basis, the EEI was born and is a measure of compliance of products based on an Energy Efficiency Index of the pump and its accompanying electric motor fitted by the manufacturer (Graph 1).

Europump, cooperated with European legislators to ensure that product was available from several manufacturers that could meet an EEI target of 0.27 by 2012 and this was amended to 0.23 in 2015.

As progress had been made on circulators, attention turned to water pumps. Since a wide range of water applications are found in Europe, this proved to be a more challenging task. Pump wet ends were available in a variety of forms and the method for attaching standard electric motors had been developed to meet operational requirements of particular applications.

Graph 1: Summary of EuP/ErP legislation and ecodesign requirements concerning pumps and motors

This led to Europump preparing a guide on the products to be covered in what is commonly known as the “Product Approach”.

Europump Guide

Guideline on the application of COMMISSION REGULATION (EU) N° 547/2012 implementing Directive 2009/125/EC of the European Parliament and the Council with regard to ecodesign requirements for water pumps

25 October 2012

Pumps in the scope

Article 1 of the regulation describes the applicable scope:

“This Regulation establishes ecodesign requirements for the placing on the market of rotodynamic water pumps for pumping clean water, including where integrated in other products.”

A definition in Article 2 of REgulation EU 547/2012 of the term ‘water pump’ specifies this scope further.

“water pump’ is the hydraulic part of the device that moves clean water by physical or mechanical action and is of one of the following designs:

• End suction own bearing (ESOB);

• End suction close coupled (ESCC);

• End suction close coupled inline (ESCCi);

• Vertical multistage (MS-V);

• Submersible multistage (MSS);”

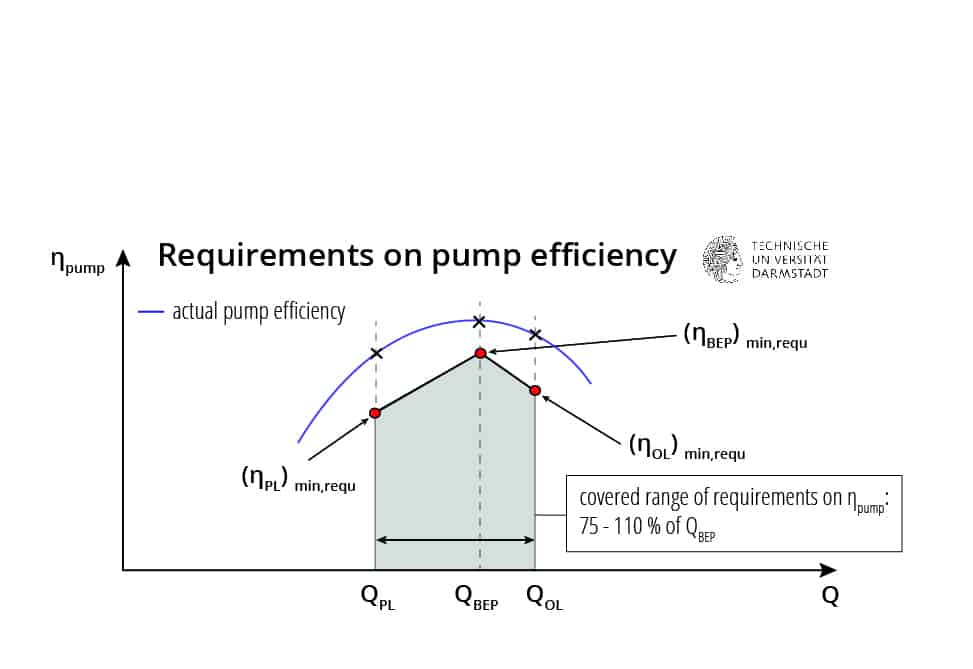

This document was preceded by work at the University of Darmstadt under the guidance of Professor Dr Bernd Stoffel, which he presented at a Europump Round Table in October 2011. This introduced some new concepts including that of the “house of efficiency” – looking at pump efficiency over a range from 75 per cent of BEP flow to 110 per cent of BEP flow – recognising that pumps cannot always be selected to operate at BEP (Graph 2).

Graph 2: Requirements on pump efficiency

Values of minimum required pump efficiency

• Were elaborated by a study at TU Darmstadt are based on:

» Statistical evaluations of data of nearly 2400 “state of the art” pumps of European manufacturers

» General fluid dynamic laws and technological aspects

As a result, the MEI was developed to provide a basis for comparison of standard pumps of particular types and a definition of Minimum Efficiency Index was determined and published in the Europump Guide.

Minimum Efficiency Index – MEI

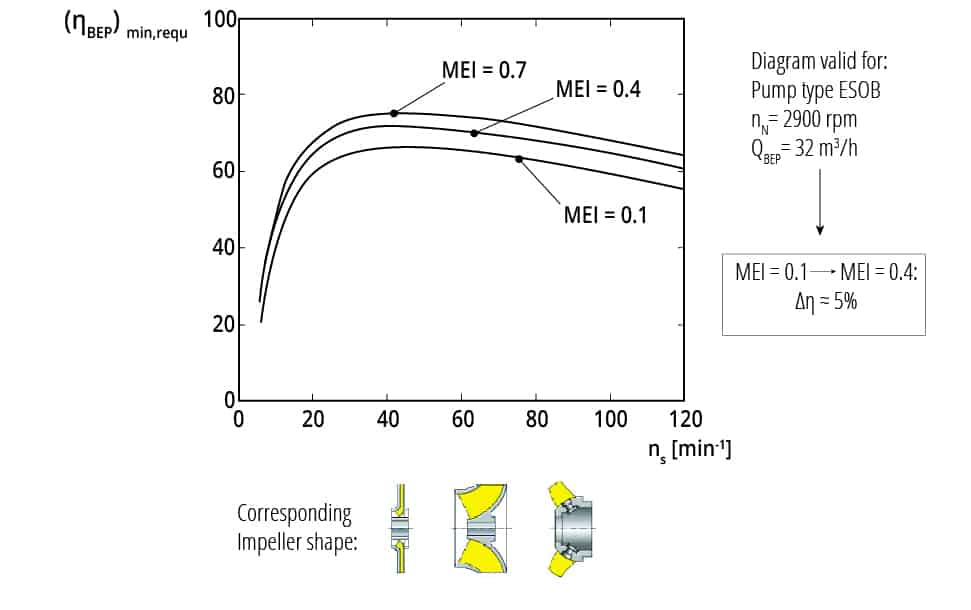

Water pumps differ greatly in efficiency depending on their size and their design. Larger pumps have a high potential to achieve better efficiencies. If efficiencies are printed on water pumps, efficiency-focused customers may overestimate the size of pump required. In order to achieve a comparable efficiency threshold-value across all legally covered water pumps, an index of pump size, specific speed and rotational speed has been created – the MEI.

MEI covers best point, part load and overload efficiencies as water pumps may be chosen with safety margins and hence do not run at best efficiency point. This ensures high and flat efficiency curves and consequently an efficiency operation in real life.

Once there was basis for determining the values of MEI for the various types of pumps within its scope, some milestones needed to be created in a similar way to those set down for circulators. MEI’s of 0.1 were introduced in 2013 and these were increased to 0.4 in 2015. Many European manufacturers supply product to meet the target MEI of 0.4, while some of the leading manufacturers can meet an even higher MEI of 0.7. Graph 3 indicates the relationship between MEI, efficiency and specific speed.

Graph 3: The relationship between MEI, efficiency and specific speed

As noted earlier, the MEI applies to the pump end, whether it is mounted on its own bearings (ESOB) or is close coupled to the driver (ESCC) with some form of fixed coupling directly to the motor shaft. The electric motor should comply with a motor standard and this is also a product approach for the driver. It is anticipated that as the industry adopts this legislation, pumps and motors will come from a single supplier and then an EEI will be set for such products. Coverage has been extended to vertical multistage (MS-V) and submersible multistage (MSS). In Europe, Directives have been enacted already and products can now be tested and certified by CE marking. This is done by the product manufacturers and provides important information to potential users of these products.

Regulation EU 547/2012 requires minimum efficiencies for the placing on the market of water pumps expressed by an index called MEI. Products already placed on the market and serviced or maintained are considered outside the scope.

• CE marking and Declaration of Conformity

• Pumps within the scope of this regulation cannot be CE marked if they do not fulfill the ecodesign and product information requirements (either within or outside the EU)

• Pumps outside the scope of this regulation can be CE marked if they fulfill all other relevant directives

• Pumps outside the scope of this regulations except for the product information requirement (water pumps designed for below -10 or above 120–) can be CE marked with reference to this regulation

• The harmonised test standard for REgulation EU 547/2012 is EN16480

• As stipulated in Article 5 of the ErP Directive 2009/125/EC, a declaration of conformity according to Annex

VI of the same Directive must be issued in order to place on the market a pump within the scope of Regulation EU 547/2012

• The declaration of conformity must refer to the ErP Directive 2009/125/EC implemented by Regulation EU 547/2012

It is interesting to note there is a good degree of harmonisation of regulations between the US and Europe, so the trend towards adopting MEI and EEI targets is likely to accelerate. Generally speaking, Australia tends to follow European standards and regulations where they are appropriate for this market. Our units of measure and power frequency means that ISO standards are easily adopted and many of the multinational companies supplying into this market are able to meet customer needs for complying products. For companies who produce their own pump ranges, it will be important to come up to speed on these requirements, since it may be only a matter of time before the regulators in Australia will consider similar action.

References

Europump Guide – 1st Edition Sept 2012

Europump Round Table – Prof Dr Bernd Stoffel – What it means in technical terms – the work done so far with Ecopump – October 2011