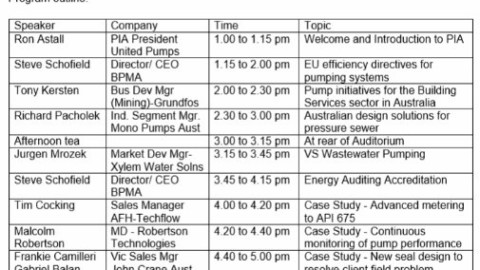

Ron Astall, United Pumps Australia

Ask ten different pump engineers for their guidelines on establishing centrifugal pump minimum flow and you might get ten different answers. Even agreeing on a basic definition for minimum flow can be problematic.

A definition that at first glance seems more than reasonable is as follows: The lowest pump flow that can be maintained continuously without sustaining damage.

So if I always operate my pump above this “minimum flow” will my pump will never wear out? Wrong! Pumps can wear out anyway even if operated at Best Efficiency Point (BEP). So we have to assume that we are talking about avoiding accelerated wear. What rate of wear is acceptable? Is it based on bearing life considerations or is internal erosion also considered? Where do we draw the line and who decides on the criteria? Should it be based on vibration criteria?

The American Petroleum Institute standard API 610 for the oil and gas industries uses vibration criteria to define “minimum continuous stable flow” as the lowest flow at which the pump can operate without exceeding the vibration limits imposed by this International Standard. This is not a bad definition because a vibration criterion implies a certain level of internal havoc within the pump and if we stay away from bad vibration, the pump must be ok. Sounds good, but there are a number of pumps that remain externally smooth at very low flows; even down to zero flow, without exceeding the API 610 vibration limits. Thus the vibration approach is not useful in all instances.

What about temperature rise? For some pumps such as multistage units or when handling liquids that easily vaporise, temperature rise at low flows may also impose limits. This can be a particular issue in multistage pumps that use balance disks or similar devices to control axial thrust; where the liquid temperature rise may be sufficient to cause vaporisation when bled back to lower pressure regions.

Instead of agonising about the best definition right now, let us instead have a look at what happens inside a centrifugal pump at various off design flows. See Fig 1.

Fig 1 is generalised but provides a convenient overview of the symptoms associated with low flow operation issues such as:

• Increased internal turbulence

• Recirculation

• Increased pressure fluctuations

• Increased vibration due to the above

• Increased axial thrust – depending on pump hydraulic balance method

• Increased radial thrust; particularly with single volute casings

• Temperature rise due to high internal energy loss

We will look at some of these in more detail.

Internal turbulence

The Best Efficiency Point (BEP) is where a centrifugal pump works best. This is the flow the hydraulic passages in pump were designed for, where the fluid velocities most closely match the geometries of the impeller and the casing, where the pressure distribution around the impeller(s) is symmetrical and where hydraulic passage entry and exit are the smoothest.

Operating away from BEP moves the velocity profiles away from this ideal, leading to compromised flow, inevitable turbulence and recirculation. An excellent analogy is a sailboat; with the sail being equivalent to the vanes of the impeller. At BEP the sail is correctly angled to the wind. Away from BEP the sail will flap or flutter. The further away from BEP, the worse it gets.

Fig 2 shows a simplified representation of smooth flow at BEP versus the sort of flow disturbances that occur at reduced flow. It does not take much imagination to realise that the distorted flow and turbulence will become worse the further away you get from BEP.

The degree of turbulence and associated vibration and buffeting depends on the hydraulic design and on the energy levels in the pump. The effects are generally worse for impellers with relatively large entry diameters. In larger higher energy pumps, vortexing (recirculation) can be so severe that cavitation like effects ensue. It is possible to get quite intellectual about this and we could discuss here such aspects as the influence of Suction Specific Speed (Nss) and the theoretical onset of recirculation. For the sake of simplicity these details will be left for a later article.

Axial thrust

Hydraulically unbalanced impellers generate an axial thrust that is proportional to the differential head. Refer to Fig 3 for a simplified representation of this effect. At reduced flow, the differential head will be higher and the generated axial thrust will increase. In multistage pumps this thrust is generally handled by a balance device that will automatically compensate, or by having impellers facing opposite ends of the pump.

Single stage pumps with hydraulically unbalanced impellers will experience higher axial thrusts at low flow, as will multistage pumps without a balancing device; such as vertical turbine pumps. Hydraulically balanced designs are theoretically unaffected.

A less predictable aspect, however, is the problem of axial shuttling that may sometimes occurs due to recirculation and flow reversals at low flow. Significant axial shuttling will not only load up the thrust bearings but will also play havoc with mechanical seal reliability.

Radial thrust – volute casings

All the flow path geometries in the pump are designed for BEP velocities. When a pump is operated away from BEP, the velocity profile is distorted. At low flow, the impeller is still trying to push out the liquid at design velocities but as flow progresses around the volute the velocity profile must slow down to match the outlet flow. This results in a higher pressure distribution towards the exit and hence a higher average pressure in this region of the casing. This acts on the periphery of the impeller and creates a radial (side) thrust which is, of course transmitted via the impeller to the shaft and bearings. See Fig 4.

This side loading on the shaft can be quite severe and has even been known to lead to shaft breakage in lighter construction pumps as well as considerable reduced bearing life. Some “Heavy Duty” pump standards such as API 610 specify minimum bearing life to be calculated at zero flow as well as at rated flow for this reason.

Pumps with double or staggered volutes are often used to minimise this effect. A double volute pump casing can reduce this radial loading to around a quarter of that of an equivalent single volute.

If low flow operation is expected to be a regular feature of a particular application, it would be wise to request bearing life calculations at the low flow duty and where practical, seek out double volute construction along with a heavy duty shaft and bearing arrangements.

Temperature rise

An eighty percent efficient pump turns eighty percent of the input shaft power into useful flow and pressure. What happens to the other twenty percent? This twenty percent energy loss basically goes into heating the pumped liquid. Indeed, there are metering devices available that accurately measure the fluid temperature difference between the pump inlet and outlet to determine pump efficiency from the temperature rise.

Efficiency reduces dramatically at low flow. Consider a ten kilowatt pump operating with an efficiency of thirty percent. In reality, this is a three kilowatt pump and a seven kilowatt heater. The formula for calculating temperature rise across a pump is very simple.

See Fig 5.

If you are on the ball, you will have spotted that “n” in the Delta T formula is pump efficiency which is of course zero at zero flow. If you are even a passable mathematician, you will also have worked out that one divided by zero is equal to infinity. Yes, the theoretical temperature rise in a pump at zero flow is infinite!

Yes, this is scary and yes the reality is that pumps get very hot very quickly at zero flow. See Fig 6.

OK, in a single stage pump it is unlikely that you will vaporise the liquid provided there is at least some flow going through the pump, but in a multistage pump, temperature rise can be a real issue in the latter stages; particularly when a pump has balance devices that bleed off warmer liquid back to lower pressure areas. In these circumstances, the bleed off liquid may vaporize and damage the internals.

Minimum flow?

The preceding discussion has focused on what happens inside a centrifugal pump at low flows. The big question is where do we draw the line to determine “minimum flow”? In other words, when do the negative effects become a pump reliability issue? This is a judgement call and there is no simple answer to this question.

There are too many different types of pumps and pumping environments to make a single generalised rule. Any decision on a minimum flow values will always be a trade off between convenience and pump reliability.

My recommendation is to be guided by the manufacturer where possible.

An excellent clue is also normally provided by the manufacturer’s published performance curves. Refer Fig 7.

Where the manufacturer ceases to show information such as efficiency or NPSHR, this is a strong hint that they do not expect the pump to be operated in this region. When in doubt, ask. ■

In Part Two of this discussion, we will look at Suction Specific Speed and the associated implications for low flow instability