Contracts for the provision of ship- mounted plants which will supply potable and process water to crews involved in the recovery of liquefied natural gas (LNG) and hydrocarbons from the Ichthys field in the Timor Sea have been awarded to leading Australian desalination specialist, Osmoflo.

Click here for a basic guide on pump services in the LNG industry

South Korean conglomerates Daewoo Shipbuilding Marine Engineers and Samsung Heavy Industries selected Osmoflo following a global tendering process. Osmoflo design, sales and commercial staff from Adelaide and its branch in Pune, India were involved in the successful bid which included intensive contract negotiations in South Korea.

Both vessels are currently under construction in South Korean yards. On one Osmoflo will provide a single pass reverse osmosis plant consisting of two 100 kilolitre per day (KL/d) trains which will process seawater to potable standard. Further treatment including remineralisation, ultra violet (UV) sterilisation and NRMB conditioning will provide high purity process water which will be used to clean generator turbine blades.

The second ship will have a two pass reverse osmosis system in two 150kL/d trains to process seawater for potable requirements.

Both plants are being constructed at Osmoflo’s main facility in Burton will be of robust design and will be configured to meet stringent oil and gas industry, marine and environmental requirements. They will be fitted and commissioned before the vessels leave the shipyards.

The ships will be permanently moored at a location some 440 km north of Broome and 800 km from Darwin. The first will partially process recovered gas to remove water, raw liquids and condensate prior its transportation by pipeline to an on-shore processing facility at Blaydon Point, Darwin.

Condensate and other liquids will be transferred to the second vessel for further processing and subsequent transfer by tanker to a refinery. While the vessels are on station, Osmoflo will provide continuing operations and maintenance support.

Osmoflo has previous experience in ship- mounted reverse osmosis desalination. At one stage during the construction of an LNG processing facility at Barrow Island – part of the Gorgon project – Osmoflo provided a plant mounted on the deck of an oil rig supply vessel which dealt with a temporary spike in desalinated water requirements.

Currently under construction at a cost in excess of $40b the Ichthys project includes the development of Timor Sea wells, a connecting pipeline to Darwin and the construction of a large processing facility. Lead developer is the Japanese company INPEX. The Darwin facility will initially produce 8.4 million tonnes of LNG per annum and 1.6 million tonnes of liquefied petroleum gas as well as approximately 100,000 barrels of condensate per day at peak.

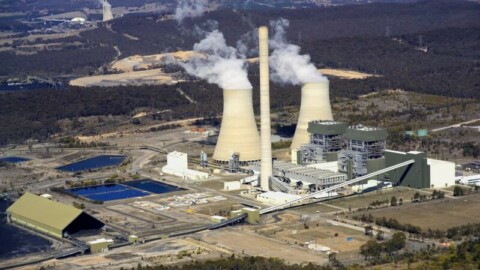

Last year Osmoflo was awarded a contract for a membrane based demineralisation plant which will provide 1,565kL/d of high purity water to a new power station that will provide electricity to the Darwin processing facility.

These latest contracts consolidate Osmoflo’s position as a preferred supplier to the LNG industry. All three massive LNG projects currently under development off the north- west coast of Australia, Gorgon, Wheatstone and now Ichthys have placed multiple orders with Osmoflo for desalination systems.

“The oil and gas sector demands a rapid response and high compliance with industry standards from its service companies along with the capability and competitiveness to participate in global tendering. Osmoflo is structured to enable us to provide world’s best practice at the right price, factors that account for our continuing success in this industry sector,” said Marc Fabig, Osmoflo Managing Director.