With its EP series and VY series, Vogelsang GmbH & Co. KG from Essen (Oldenburg), Germany, is launching two new pump series that meet the high demands of industrial use. The rotary lobe pumps are made of a flow-optimised one-piece housing and are therefore particularly efficient. They reliably convey thin-bodied as well as highly viscous, pure and solids-containing media at temperatures of up to 200°C. The pumps are ATEX and TA-Luft compliant and thus suited for use in highly demanding areas such as the oil, gas and chemical industries.

Thanks to increased efficiency and added seal versatility, Vogelsang is able to open up new areas of application for its proven pump technology.

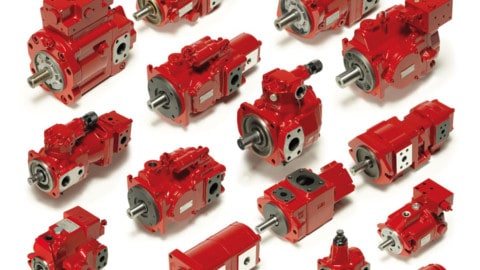

As the inventor of the elastomer-coated rotary lobe pump in 1970, Vogelsang has been for decades one of the world’s leading companies in the field of pumps.

EP series: rotary lobe pumps with up to 18 bar pressure

The EP series is designed for extreme conditions and permanently high pressures. Its high-performance gearbox allows for a constant pressure output of up to 18 bar, making it unique on the market today.

The pumps of the EP series consist of a one-piece housing made from either cast iron or stainless steel. Helical gears in the gearbox ensure smooth performance and reduce noise emissions. Pulsation-free transferring reduces wear on the adjacent pipeline to a minimum.

The high-pressure performance and temperature limit of 200°C, along with its seal versatility, make the EP series suitable for applications for which companies previously used screw, gear and progressing cavity pumps.

These include the oil and gas sector, tank farms, the petrochemical industry, and the production of paints and varnishes, paper, glue and sugar.

Vogelsang has additionally equipped its EP series with an AirGap for increased operational reliability. This gap atmospherically separates the gearbox and the pump chamber, ensuring that in the event of a leak, liquid will drain out rather than entering the gearbox.

Exploded view EP series: The helical high-performance gearbox allows pressures of up to 18 bar.

VY series: a highly efficient all-rounder

VY series rotary lobe pumps are based on Vogelsang’s proven VX series. The versatility of the VY series makes it suitable for use in the chemical industry, as well as in the paper sector. The performance spectrum ranges from 1m³/h to 120m³/h at a maximum pressure of 10 bar.

Integrated sensors provide all important information about the pump’s operating status. The VY series is also available with axial and radial wear protection for media with abrasive components.

Seal versatility for increased flexibility

A variety of different sealing systems can be used in the housing of the new pump series depending on the industry specific standard and requirement. In addition to the Vogelsang Quality-Cartridge, further special mechanical seals are available for the EP and VY series.

Vogelsang worked with leading manufacturers to develop the CoX-Cartridge and offer the right solution for a variety of applications; from use in oil and sugar production, to conveying hot, chemically demanding media or latex paints. The seal’s robust design also makes it suited for high-pressure use. The new pump series can also be equipped with mechanical seals according to API 682 if required.

Service-friendly assembly and cleaning

For increased ease of service, both pump series feature a quick connection. Thanks to this, pipelines can be connected to pumps in a matter of minutes. The Quick-Service cover allows access to all internal components.

Furthermore, when designing the EP and VY series pumps, the engineers placed significant importance on easy cleaning. The pumps can be rinsed and disinfected according to the CIP (Cleaning in Place) and SIP (Sterilisation in Place) cleaning procedures.

The housing design also reduces dead space to a minimum, thus preventing liquids from accumulating in gaps or uneven surfaces.

This sponsored editorial is brought to you by Vogelsang. For more information, visit www.vogelsang.info/.