Industry 4.0 is ushering in a new era for industry, with more intelligence and connectivity, combining machines, computers and the internet to make systems smarter. This has implications for industrial motor control, especially for mature technologies like soft starters.

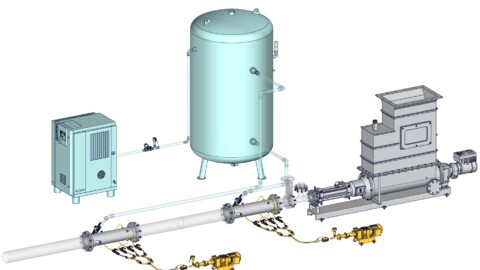

With the right technical capability (e.g. interchangeable smart processor cards), soft starters can control a whole system by connecting directly to other devices such as pressure, flow and depth sensors in a pumping application.

They can also become more efficient. According to the International Energy Agency, electric motors account for 69 per cent of total industrial electricity consumption in the world.

Reducing this consumption is important. Around 80 per cent of motor applications are most effective with fixed speed. Selecting the correct control mode for the application (fixed or variable speed) is critical for true energy efficiency.

Embracing more energy efficient motors

Engineers are embracing the use of new generation ‘premium efficiency’ motors. IE3 motors are more efficient than IE2 motors, resulting in lower lifetime energy usage and energy costs, which has obvious value.

However, other IE3 motor characteristics are affected by the changes made to achieve this efficiency.

This includes starting issues such as higher inrush and starting currents that stress electrical supply circuits, and spiky pull out torque curves that can make smooth control of acceleration and deceleration more difficult.

Soft starters can address this by limiting inrush and starting current to the minimum necessary to start, which enables design of efficient distribution circuits and prevents breaker trip due to motor starting.

Soft starters also precisely control the starting and stopping of IE3 motors, offering control over acceleration and deceleration to cater for motors with tough torque curves.

An internally bypassed soft starter is 99.5 per cent efficient when running, which equates to a potential 80 per cent reduction in waste energy compared to a misapplied variable speed drive.

It also produces no harmonics during run, improving overall power quality and eliminating system losses resulting from harmonics.

More than energy savings

In addition to energy savings, Industry 4.0-ready soft starters offer:

Ease of use for technical staff: A graphical display with multiple languages and in-built intelligence such as application setup menus make installation and commissioning easier and faster.

The ability to replicate these settings across multiple starters by extracting parameter information using a standard protocol like USB is also important.

Ability to extract and share data: Connecting with other devices and support services must be straightforward, including a range of communications modules enabling network connections.

Mobile technology is also being leveraged by soft starter manufacturers, with smartphone app access to extracting starter and performance information for analysis and sharing.

Automation capabilities: Built-in timers and schedulers improve system efficiency and allow operations to be tailored to a site’s requirements. Automatic resets and flexible protection options can be programmed to eliminate manual interventions and ensure continued operation.

Operational reliability: This includes starter, motor and system protection functions and associated notification and alarm capability, and features like emergency override to suppress all protections for a situation when the machine simply has to run.

This partner solutions was brought to you by IPD Industrial. For more information, visit http://www.ipdgroup.com.au/.